In a bold move that signals the industry’s shift towards digital transformation in construction, Robertson Construction Group announces a comprehensive $50 million technology initiative aimed at revolutionizing their project delivery methods. This strategic investment encompasses artificial intelligence for project planning, IoT sensors for real-time site monitoring, and advanced Building Information Modeling (BIM) integration across all operations. By leveraging cutting-edge digital solutions, the firm projects a 30% increase in operational efficiency and a 25% reduction in project completion times. The initiative represents a significant departure from traditional construction methodologies, positioning Robertson at the forefront of the industry’s technological evolution while addressing growing demands for smart construction solutions and sustainable building practices. This transformation will fundamentally reshape how the company approaches project execution, risk management, and client collaboration in an increasingly digitized construction landscape.

Digital Transformation Strategy

Key Technology Investments

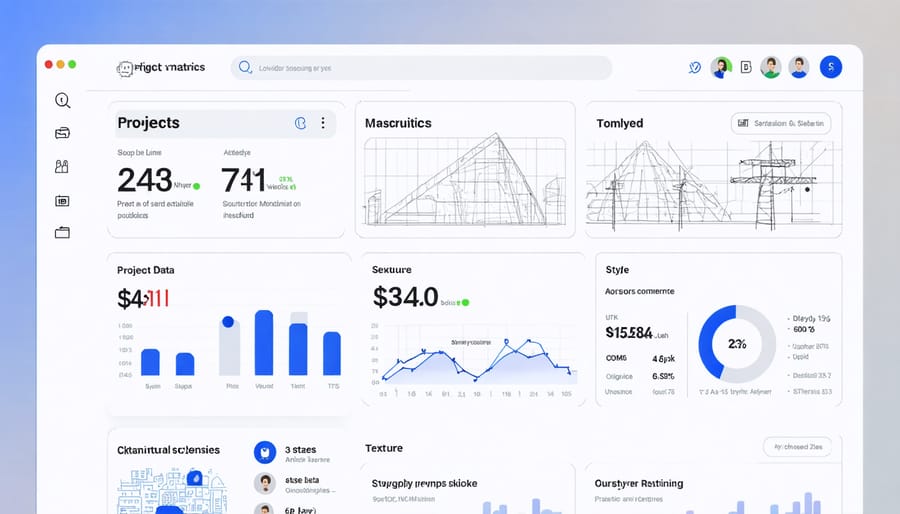

The firm’s technology investment strategy centers on three core pillars: Building Information Modeling (BIM), Artificial Intelligence, and Internet of Things (IoT) solutions. A significant portion of the budget has been allocated to implementing Autodesk BIM 360, enabling real-time collaboration between project teams and streamlining the design-to-construction workflow. This platform will serve as the central hub for project documentation, model coordination, and quality control processes.

On the AI front, the company is deploying machine learning algorithms for predictive maintenance and risk assessment. These systems analyze historical project data and real-time inputs to forecast potential delays, equipment failures, and safety hazards. The AI implementation includes computer vision technology for progress monitoring and automated quality inspections.

IoT solutions form the third technological cornerstone, with smart sensors being installed across construction sites to monitor environmental conditions, equipment utilization, and worker safety. The company is implementing a network of connected devices that provide real-time data on concrete curing conditions, structural stress, and equipment performance. This IoT ecosystem integrates with the firm’s cloud-based project management platform, enabling data-driven decision-making and improved operational efficiency.

Implementation Timeline

The implementation timeline spans 24 months, divided into four strategic phases to ensure seamless technology integration. Phase One (months 1-6) focuses on infrastructure development, including cloud-based system deployment and initial hardware procurement. During this period, the firm will establish a dedicated digital transformation team and conduct comprehensive staff assessments.

Phase Two (months 7-12) introduces core digital tools and initiates basic training programs. Key technologies like BIM software, project management platforms, and mobile field applications will be rolled out gradually to minimize disruption to ongoing projects. The firm will implement a mentor-based learning system, pairing digitally proficient staff with those requiring additional support.

Phase Three (months 13-18) expands implementation to include advanced technologies such as drone surveying, IoT sensors, and augmented reality applications. This phase emphasizes intensive training programs and real-world application through pilot projects. The firm will also establish partnerships with technology vendors for specialized training and support.

The final phase (months 19-24) focuses on optimization and integration of all systems, ensuring comprehensive adoption across departments. This phase includes performance monitoring, workflow refinement, and establishing long-term maintenance protocols. Regular evaluation meetings will track progress and address any implementation challenges.

Skills Development Framework

Training Programs

To ensure successful technology adoption, the firm has developed comprehensive construction skills development programs in partnership with leading technology providers and educational institutions. The initiative includes a three-tiered training approach, beginning with foundational digital literacy courses for all employees, followed by specialized technical training for specific roles and advanced certification programs for key personnel.

The firm has established a dedicated Digital Learning Center, equipped with VR simulation stations and BIM modeling workstations, where employees can gain hands-on experience with new technologies in a controlled environment. Partnership agreements with software vendors ensure that staff receive certified training on the latest construction management platforms, including Procore, Autodesk Construction Cloud, and PlanGrid.

To address the diverse learning needs of their workforce, the training programs incorporate both instructor-led sessions and self-paced online modules. The firm has also implemented a mentorship program where digitally proficient team members guide colleagues through technology adoption challenges. Regular assessment workshops measure progress and identify areas requiring additional support.

The training calendar is structured to minimize disruption to ongoing projects while ensuring continuous skill development. Monthly technology forums provide opportunities for team members to share experiences and best practices, fostering a culture of collaborative learning and innovation.

Workforce Adaptation

Successfully integrating new technology requires a well-planned workforce adaptation strategy. Our research shows that construction firms achieving the highest ROI from digital transformation invest significantly in employee training and development programs.

A comprehensive skills assessment is the first critical step, enabling firms to identify knowledge gaps and create targeted training programs. Industry leaders recommend a tiered approach, starting with basic digital literacy and progressing to advanced technology-specific training.

Construction professionals benefit most from hands-on learning environments. Implementing mentor-mentee partnerships between tech-savvy employees and those less familiar with digital tools has proven particularly effective. This approach creates a supportive learning environment while maintaining productivity during the transition period.

Change management plays a crucial role in workforce adaptation. Regular communication about technology benefits, clear implementation timelines, and addressing concerns proactively helps reduce resistance to change. Companies successfully managing this transition typically establish dedicated support teams to provide real-time assistance during the learning phase.

Continuous feedback loops and performance monitoring help identify areas requiring additional support. Leading firms are implementing micro-learning modules and mobile training applications, allowing workers to learn at their own pace while maintaining daily responsibilities.

Investment in proper training and support typically represents 15-20% of the total technology implementation budget, but firms report this investment delivers substantial returns through improved adoption rates and reduced implementation time.

Expected Business Impact

Productivity Gains

The implementation of advanced digital solutions is projected to significantly boost productivity through technology across multiple project phases. Initial forecasts indicate a 35% reduction in project documentation time and a 25% decrease in rework requirements through the integration of Building Information Modeling (BIM) and real-time collaboration tools.

Analysis of similar implementations across the industry suggests that automated progress tracking and AI-powered scheduling could reduce project timelines by up to 20%. The firm expects to achieve substantial improvements in resource allocation, with intelligent material management systems potentially cutting waste by 30% and improving inventory turnover by 40%.

Field operations are anticipated to see the most dramatic efficiency gains, with drone surveys and IoT sensors enabling faster site inspections and real-time quality control. Labor productivity is projected to increase by 25% through better task coordination and reduced idle time. Additionally, the integration of mobile apps for field reporting is expected to save an average of 5 hours per week per supervisor.

These improvements are expected to translate into faster project delivery times, with most projects anticipated to finish 15-20% ahead of traditional schedules while maintaining higher quality standards and improved safety metrics.

Competitive Advantage

In today’s competitive construction landscape, developing robust digital capabilities creates a distinct market advantage. By investing in technology and digital skills development, forward-thinking construction firms position themselves as industry leaders rather than followers. This strategic approach enables companies to deliver projects more efficiently, reduce costs, and provide enhanced value to clients.

The integration of digital tools and expertise allows firms to tackle complex projects with greater precision and confidence. Advanced modeling capabilities, data analytics, and digital collaboration platforms enable teams to identify and resolve potential issues before they impact project timelines or budgets. This proactive approach significantly reduces risk and increases client satisfaction.

Furthermore, firms with strong digital competencies attract top talent and maintain higher employee retention rates. Today’s construction professionals seek opportunities with companies that embrace modern technologies and provide continuous learning opportunities. This creates a positive feedback loop where enhanced digital capabilities lead to better project outcomes, stronger client relationships, and increased market share.

By establishing a reputation for technological proficiency, construction firms can differentiate themselves when bidding on projects, particularly those requiring sophisticated digital deliverables or complex coordination. This competitive edge often translates into preferred partner status with major clients and higher-value contract opportunities.

Industry Implications

The adoption of advanced technology by construction firms signals a transformative shift in the industry landscape. As more companies embrace digital solutions, we’re witnessing a ripple effect that extends far beyond individual organizations. This technological integration is reshaping traditional construction methodologies and creating new standards for project execution and workforce development.

Industry experts predict that firms implementing comprehensive digital strategies will gain a significant competitive advantage, potentially securing up to 30% more contracts than their traditional counterparts. This trend is compelling other construction companies to accelerate their own digital transformation initiatives or risk falling behind.

The impact on workforce development is equally significant. The construction sector is experiencing a fundamental shift in skill requirements, with an increasing demand for workers who can effectively combine traditional construction expertise with digital competencies. Educational institutions and training programs are already adapting their curricula to address this evolution, preparing the next generation of construction professionals for a technology-driven environment.

Furthermore, this technological adoption is fostering unprecedented collaboration between construction firms, technology providers, and educational institutions. These partnerships are essential for developing industry-specific solutions and ensuring a steady pipeline of skilled workers. As more firms embrace digital transformation, we can expect to see standardization of digital practices, improved project outcomes, and enhanced industry-wide efficiency metrics.

This strategic technological initiative represents a significant turning point in construction industry modernization. By embracing digital transformation, the firm positions itself at the forefront of innovation while addressing crucial challenges in productivity, safety, and project delivery. The comprehensive approach to technology integration, coupled with strategic workforce development, sets a compelling precedent for industry-wide evolution. As construction firms globally face increasing pressure to modernize, this initiative demonstrates how thoughtful technology adoption can drive tangible business outcomes. Looking ahead, the success of this program will likely influence similar transformations across the sector, potentially reshaping industry standards and best practices. The commitment to continuous improvement and adaptation ensures the firm remains competitive while contributing to the broader advancement of construction technology implementation.