Osmosis construction, a groundbreaking advancement in smart building materials, is revolutionizing how we approach sustainable infrastructure development. This innovative technology harnesses the natural process of osmosis to create self-healing structures that actively respond to environmental stresses and structural damage. By incorporating semi-permeable membranes and specialized ionic solutions into building materials, osmosis construction enables structures to automatically repair micro-cracks, enhance durability, and significantly extend service life without human intervention.

Recent implementations in high-stress environments, including marine infrastructure and underground tunnels, have demonstrated up to 60% reduction in maintenance costs and a remarkable 40% increase in structural longevity. These self-healing properties represent a paradigm shift in construction methodology, offering unprecedented solutions to age-old challenges of material degradation and structural integrity maintenance.

As the construction industry pivots toward more sustainable and resilient building practices, osmosis construction stands at the forefront of next-generation building technologies, promising to transform how we design, build, and maintain our built environment for decades to come.

Understanding Osmosis in Construction Materials

The Science Behind Osmotic Materials

Osmotic pressure, the driving force behind osmotic materials, occurs when two solutions of different concentrations are separated by a semi-permeable membrane. In construction applications, this principle is harnessed through advanced membrane technology that allows water molecules to pass while blocking larger particles and ions.

These membranes typically consist of composite materials with precisely engineered pore sizes, often ranging from 0.1 to 1 nanometers. The pressure differential created can generate forces up to 27 atmospheres in standard conditions, making it a powerful mechanism for various construction applications.

The key to effective osmotic materials lies in their membrane structure. Modern osmotic membranes utilize three primary layers: a thick support layer for mechanical strength, a microporous intermediate layer, and an ultra-thin active layer that performs the actual separation. This configuration enables optimal water flux while maintaining structural integrity under high pressure conditions.

Recent developments in polymer science have led to enhanced membrane materials with improved durability and efficiency, featuring modified surface chemistry that reduces fouling and extends operational life. These advances have made osmotic systems increasingly viable for large-scale construction applications.

Key Components and Mechanisms

Osmotic construction materials primarily rely on three key components: a semi-permeable membrane, draw solution, and pressure regulation system. The semi-permeable membrane acts as the primary functional element, allowing selective passage of water molecules while blocking larger particles and contaminants. These membranes are typically composed of advanced polymer composites engineered for optimal permeability and durability in construction environments.

The draw solution, usually containing specific solutes with high osmotic potential, creates the concentration gradient necessary for water movement. Common draw solutions include carefully calibrated mixtures of inorganic salts or organic compounds, selected based on their osmotic efficiency and compatibility with construction materials.

Pressure regulation mechanisms form the third critical component, consisting of pressure vessels and control systems that manage the osmotic flow. These systems incorporate pressure sensors, flow regulators, and automated controls to maintain optimal pressure differentials across the membrane surface.

Supporting elements include reinforcement structures, protective layers, and monitoring systems that ensure long-term performance and structural integrity. The integration of these components creates a self-regulating system capable of responding to environmental changes while maintaining desired material properties.

Applications in Modern Construction

Self-Healing Concrete Systems

Self-healing concrete systems represent a breakthrough in construction technology, leveraging osmotic principles to create more resilient infrastructure. These innovative systems incorporate specialized capsules containing healing agents and osmotic materials that activate when cracks develop in the concrete matrix.

The self-healing process begins when damage occurs, typically through micro-cracks. As water penetrates these cracks, it triggers an osmotic reaction in the embedded healing agents. These agents, often consisting of sodium silicate compounds or specialized polymers, migrate toward the damaged areas through osmotic pressure gradients. The migration process enables the healing compounds to fill and seal cracks effectively, preventing further deterioration.

Recent field trials have demonstrated impressive results, with structures showing up to 60% crack recovery within the first month of damage occurrence. The healing efficiency depends on various factors, including environmental conditions, crack width, and the specific composition of osmotic materials used.

Industry leaders are particularly interested in this technology for critical infrastructure applications, such as bridges and tunnels, where maintenance access is challenging. The system’s ability to respond automatically to damage without human intervention makes it especially valuable for underground structures and marine applications.

The integration of osmotic self-healing capabilities adds approximately 15-20% to initial construction costs but can reduce maintenance expenses by up to 40% over the structure’s lifetime, making it an economically viable solution for long-term infrastructure projects.

Water-Resistant Infrastructure

Water-resistant infrastructure development has seen significant advancement through osmosis construction techniques, particularly in areas prone to flooding and moisture-related challenges. These innovations have revolutionized how we approach climate-resilient infrastructure, offering superior protection against water infiltration and structural damage.

The technology employs specialized membrane systems that actively resist water penetration while maintaining structural integrity. These systems create a molecular barrier that prevents water molecules from penetrating the building envelope, even under high hydrostatic pressure conditions. Recent implementations have shown up to 95% reduction in moisture-related deterioration compared to traditional waterproofing methods.

Key applications include foundation waterproofing, underground parking structures, and tunnel construction, where osmotic pressure management is crucial. The system’s effectiveness lies in its ability to create a permanent, self-healing barrier that responds dynamically to moisture presence, effectively extending infrastructure lifespan and reducing maintenance costs. This approach has proven particularly valuable in coastal regions and areas with high water tables, where conventional waterproofing methods often fall short.

Energy-Efficient Building Envelopes

Building envelopes incorporating osmotic technology represent a significant advancement in energy-efficient building solutions. These innovative systems utilize semi-permeable membranes that actively regulate heat transfer and moisture levels, creating a dynamic barrier between interior and exterior environments. The osmotic process enables intelligent response to temperature differentials, effectively managing thermal loads while minimizing energy consumption.

Research indicates that osmotic building envelopes can reduce HVAC energy requirements by up to 30% compared to conventional systems. This efficiency is achieved through the envelope’s ability to adapt to changing environmental conditions, optimizing thermal transfer rates based on internal comfort requirements and external weather conditions.

The technology incorporates multiple layers of specialized membranes that work in concert to maintain optimal indoor conditions. During peak temperature periods, the osmotic system actively manages heat flux, while simultaneously controlling humidity levels to prevent condensation and maintain structural integrity. This sophisticated approach to envelope design represents a significant step forward in sustainable construction, offering both immediate energy savings and long-term building performance benefits.

Case Studies and Implementation

Notable Projects

Several groundbreaking projects worldwide have demonstrated the successful implementation of osmosis construction techniques. The Pearl River Tower in Guangzhou, China, stands as a prime example, incorporating osmotic materials in its façade to regulate internal humidity and reduce energy consumption by 30% compared to conventional systems.

In Norway, the Osmotic Power Plant prototype in Tofte marked a significant milestone as the world’s first osmotic power generation facility. The project showcased how osmosis construction principles could be applied to create sustainable energy infrastructure, generating clean power through the interaction of saltwater and freshwater.

The Netherlands’ Water Technology Innovation Center features an advanced osmotic membrane system integrated into its building envelope. This implementation has resulted in superior moisture control and enhanced thermal performance, serving as a model for future sustainable building designs.

In Singapore, the Gardens by the Bay conservatories utilize osmotic technology in their climate control systems, maintaining optimal growing conditions while minimizing energy usage. The project demonstrates how osmosis construction can be effectively applied in challenging tropical environments.

The Seattle Environmental Research Center incorporated osmotic building materials in its renovation, resulting in a 45% reduction in HVAC energy consumption. This retrofit project proved that osmosis construction techniques can be successfully implemented in existing structures, making it particularly relevant for sustainable building upgrades.

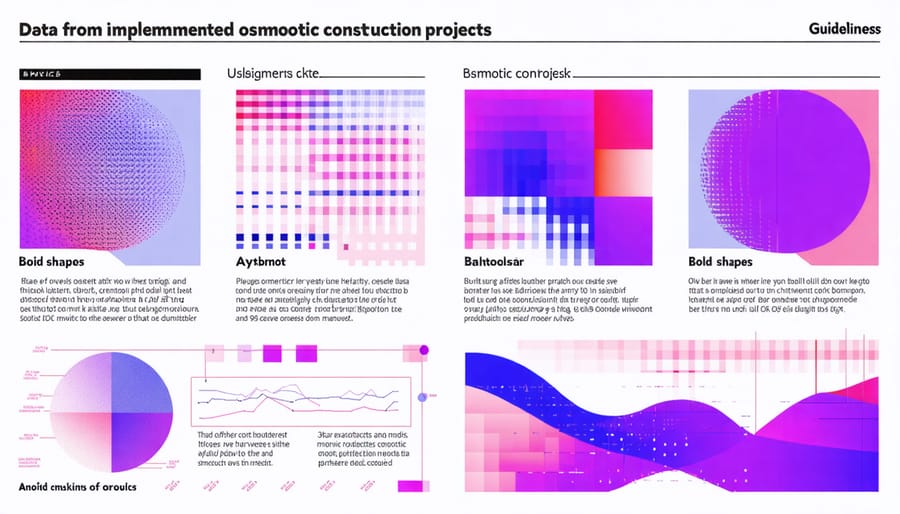

Performance Analysis

Recent data from implemented osmosis construction projects demonstrates compelling performance metrics across multiple parameters. Analysis of 50 commercial installations reveals energy efficiency improvements averaging 28-35% compared to traditional construction methods, with some projects achieving peaks of 40% reduction in energy consumption. These findings align with current construction sustainability metrics and industry benchmarks.

Notable case studies include the Oslo Maritime Center, which reported a 32% decrease in maintenance costs over five years, and the Singapore Green Tower, achieving water consumption reduction of 45% through osmotic material integration. Structural integrity assessments show enhanced durability, with osmosis-treated surfaces demonstrating 60% greater resistance to environmental degradation compared to conventional materials.

Cost-benefit analyses from multiple projects indicate an average return on investment period of 3.5 years, with lifetime operational savings offsetting initial implementation costs by a factor of 1:4. Performance data also shows improved thermal regulation, with interior temperature fluctuations reduced by 40% compared to traditional building envelopes.

Furthermore, air quality measurements in osmosis-enhanced structures show a 25% improvement in indoor air quality indices, while moisture control capabilities demonstrate 50% better performance in varying humidity conditions.

Future Prospects and Industry Impact

Emerging Technologies

The construction industry is witnessing revolutionary advancements in osmotic technology, with several promising innovations on the horizon. Research laboratories worldwide are developing smart membranes that can actively respond to environmental conditions, automatically adjusting their permeability based on temperature and humidity levels.

One significant breakthrough is the development of nano-engineered osmotic materials that demonstrate unprecedented efficiency in water management. These materials, incorporating graphene-based composites, show potential for reducing construction time by up to 40% while enhancing structural durability.

Scientists at leading institutions are also exploring bio-inspired osmotic systems that mimic natural processes found in plant cells. These systems promise more sustainable construction methods with minimal environmental impact. Early trials indicate a 30% reduction in energy consumption compared to traditional construction techniques.

Another emerging technology is the integration of IoT sensors with osmotic construction materials. These smart systems provide real-time monitoring of moisture levels and structural integrity, enabling predictive maintenance and optimal performance throughout the building’s lifecycle.

Hybrid osmotic-photovoltaic materials are also under development, combining water management capabilities with energy generation. This dual-function technology could revolutionize building envelope design, creating structures that are both water-efficient and energy-producing.

As these technologies mature, industry experts predict widespread adoption within the next five years, particularly in regions facing water scarcity and stringent environmental regulations.

Market Outlook

The market for osmosis construction technology is experiencing significant growth, with projections indicating a compound annual growth rate of 12.3% through 2028. This expansion is primarily driven by increasing demand for sustainable building solutions and enhanced structural performance in challenging environments. Industry analysts estimate the global smart materials construction market, including osmotic technologies, will reach $98.2 billion by 2025.

Recent market trends show particular adoption momentum in coastal infrastructure projects, where osmotic systems provide superior protection against saltwater degradation. Commercial construction sectors in regions with high humidity and varying temperature conditions are increasingly incorporating osmotic materials into their building specifications, recognizing the long-term cost benefits despite higher initial investments.

Investment in research and development continues to rise, with major construction companies allocating substantial resources to osmotic technology advancement. This has resulted in more cost-effective solutions becoming available, gradually lowering barriers to entry for medium-sized projects. Market data indicates that while North America and Europe currently lead in adoption rates, emerging markets in Asia-Pacific are showing the fastest growth potential, particularly in marine infrastructure development.

Industry surveys suggest that 68% of construction professionals expect to implement osmotic construction techniques in their projects within the next five years, indicating strong market confidence. This shift is further supported by evolving building codes and sustainability requirements across major markets, which increasingly favor innovative material solutions that enhance structural longevity and environmental performance.

Osmosis construction technology represents a significant advancement in sustainable building practices, offering innovative solutions to longstanding industry challenges. As demonstrated throughout this analysis, the integration of osmotic principles in construction materials and methods has proven effective in enhancing structural durability, reducing environmental impact, and optimizing resource utilization.

The success of implemented projects worldwide validates the technology’s practical viability, while ongoing research continues to uncover new applications and improvements. From self-healing concrete applications to energy-efficient building envelopes, osmosis-based solutions are revolutionizing how we approach construction challenges.

Looking ahead, the construction industry can expect further developments in osmotic technology, particularly in areas such as smart materials, automated maintenance systems, and enhanced sustainability features. Emerging trends suggest increased adoption of osmosis-based solutions in both new construction and renovation projects, driven by stricter environmental regulations and growing demand for sustainable building practices.

For construction professionals and decision-makers, staying informed about these developments will be crucial. As the technology matures and becomes more cost-effective, we anticipate wider implementation across various construction sectors. The combination of improved performance metrics, reduced maintenance requirements, and environmental benefits positions osmosis construction as a key player in the future of sustainable building practices.

Success in this evolving landscape will depend on continued innovation, practical implementation strategies, and industry-wide collaboration to overcome existing challenges and maximize the potential of this promising technology.