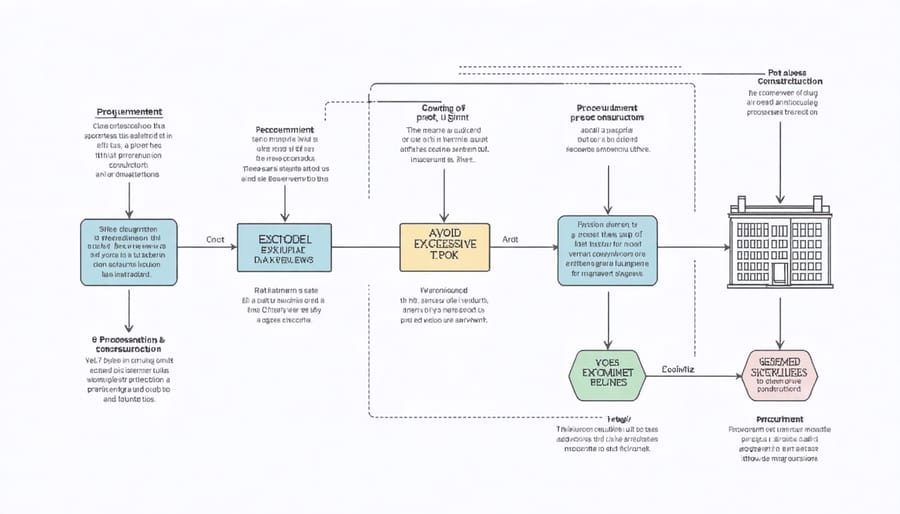

Streamline your construction operations with a systematic project procurement management framework that drives efficiency and cost control. In today’s complex construction landscape, a well-structured seven-step procurement process separates industry leaders from their competitors, delivering up to 18% in cost savings and 40% faster project completion rates.

The procurement process forms the backbone of successful construction projects, ensuring timely material delivery, vendor compliance, and quality control throughout the supply chain. From initial needs assessment to contract closure, each step builds upon the previous, creating a robust framework that minimizes risks and maximizes value. Modern construction firms leverage digital procurement platforms and data analytics to enhance traditional processes, enabling real-time tracking, automated compliance checks, and predictive analytics for superior outcomes.

Industry leaders who implement this systematic approach report significant improvements in vendor relationships, reduced material wastage, and enhanced project predictability. This comprehensive guide breaks down each step of the procurement process, providing actionable strategies, compliance checkpoints, and digital integration techniques specifically tailored for construction professionals.

Step 1: Strategic Need Assessment

Project Requirements Analysis

Project requirements analysis forms the cornerstone of successful construction procurement, requiring meticulous attention to detail and comprehensive stakeholder input. This critical phase begins with gathering detailed specifications from project stakeholders, including architects, engineers, and end-users. The process involves creating detailed documentation that outlines technical specifications, performance requirements, quality standards, and project timeline constraints.

Key components of requirements analysis include conducting site surveys, reviewing architectural drawings, assessing environmental impact considerations, and evaluating regulatory compliance needs. Project managers must also identify potential risks and constraints that could impact procurement decisions, such as material availability, local building codes, and supply chain limitations.

Modern construction projects benefit from utilizing digital tools and Building Information Modeling (BIM) to enhance requirements documentation accuracy. These technologies help visualize project needs and identify potential conflicts before procurement begins. Requirements should be documented in a structured format, typically including scope statements, technical specifications, quantity estimates, and quality benchmarks.

Success in this phase relies on effective collaboration between project stakeholders and clear communication channels. Regular validation meetings ensure all requirements align with project objectives and budget constraints before proceeding to subsequent procurement steps.

Stakeholder Alignment

Successful procurement in construction projects hinges on getting all stakeholders on the same page from the outset. Begin by identifying key stakeholders, including project owners, contractors, suppliers, design teams, and end-users. Organize initial alignment meetings to establish clear communication channels and define roles and responsibilities.

Create a stakeholder matrix documenting each party’s interests, influence levels, and potential concerns. This visual tool helps track relationships and manage expectations throughout the procurement process. Develop a comprehensive communication plan that outlines regular progress updates, milestone reviews, and feedback mechanisms.

Document all procurement objectives in a formal charter, ensuring each stakeholder explicitly acknowledges their understanding and commitment. Include specific performance metrics, quality standards, timeline requirements, and budget constraints. Address potential conflicts early by establishing a structured dispute resolution process.

Maintain alignment through regular stakeholder review meetings, where progress is measured against established objectives. Use collaborative digital platforms to share real-time updates and maintain transparency. Remember that stakeholder alignment is not a one-time exercise but requires continuous monitoring and adjustment throughout the procurement lifecycle.

Step 2: Market Research and Supplier Evaluation

Digital Supplier Discovery

In today’s digital age, construction companies are leveraging advanced technologies to streamline their supplier discovery process. Modern digital procurement platforms offer sophisticated supplier databases, automated verification systems, and real-time market analytics to identify qualified vendors efficiently.

Leading construction firms utilize specialized procurement software that integrates supplier pre-qualification data, performance metrics, and compliance documentation. These platforms enable procurement teams to filter suppliers based on specific criteria such as certifications, geographical location, capacity, and past performance ratings.

Cloud-based supplier networks have revolutionized how construction companies connect with vendors, offering features like instant messaging, document sharing, and collaborative bidding tools. Advanced algorithms help match project requirements with supplier capabilities, while AI-powered systems analyze supplier risk profiles and financial stability.

Industry-specific marketplaces provide access to specialized construction suppliers, complete with detailed catalogs, BIM object libraries, and technical specifications. These platforms often include built-in vendor comparison tools, helping procurement teams make data-driven decisions while maintaining compliance with organizational standards and regulatory requirements.

Real-time supplier discovery tools also facilitate emergency sourcing needs and help identify alternative suppliers during supply chain disruptions, ensuring project continuity and risk mitigation.

Pre-qualification Criteria

Pre-qualification criteria establish essential standards that potential suppliers must meet before participating in the procurement process. In construction projects, these criteria typically encompass financial stability, technical capabilities, safety records, and past performance metrics. A robust pre-qualification framework helps organizations identify capable suppliers while minimizing project risks.

Key evaluation areas include financial ratios, bonding capacity, and credit ratings to assess fiscal health. Technical qualifications focus on specialized equipment ownership, skilled workforce availability, and relevant certifications. Safety performance is measured through EMR ratings, OSHA compliance records, and documented safety programs.

Organizations should develop a standardized scoring matrix that weighs each criterion based on project requirements. For instance, a complex infrastructure project might prioritize technical expertise and financial strength, while a renovation project might emphasize past performance in occupied buildings.

Documentation requirements typically include audited financial statements, references from similar projects, quality management certifications, and proof of insurance coverage. Modern procurement systems often utilize digital platforms for efficient submission and evaluation of these credentials.

Regular review and updates of pre-qualification standards ensure alignment with evolving industry requirements and organizational objectives. This dynamic approach maintains the effectiveness of the supplier evaluation process while adapting to market changes.

Step 3: Strategy Development

Risk Assessment

Risk assessment is a critical component of the procurement process, requiring thorough evaluation of potential threats that could impact project success. Key areas to assess include supplier reliability, market volatility, quality control issues, and delivery timeline risks. Construction professionals should develop a comprehensive risk matrix that categorizes risks based on their probability and potential impact.

Financial risks warrant particular attention, including currency fluctuations, material price escalations, and supplier financial stability. Additionally, consider operational risks such as supply chain disruptions, regulatory compliance issues, and capacity constraints. Environmental factors and force majeure events should also be factored into the assessment.

Effective risk mitigation strategies include developing contingency plans, establishing multiple supplier relationships, implementing quality control measures, and securing appropriate insurance coverage. Contract terms should clearly define risk allocation between parties and include provisions for dispute resolution.

Regular monitoring and updating of risk assessments throughout the procurement cycle ensures early identification of emerging threats. Document all identified risks and mitigation strategies in the procurement plan, enabling better decision-making and proactive risk management. This systematic approach to risk assessment helps safeguard project objectives and maintain procurement efficiency.

Cost-Benefit Analysis

A thorough cost-benefit analysis helps organizations evaluate different procurement approaches and select the most efficient method for their specific project needs. This critical step involves analyzing various factors, including direct costs, lifecycle expenses, potential risks, and long-term value generation. Procurement teams should assess multiple vendors’ proposals against predetermined evaluation criteria, considering both quantitative metrics and qualitative factors.

Key considerations include initial purchase price, implementation costs, maintenance requirements, and potential return on investment. Effective cost control strategies must be implemented to ensure the selected procurement approach aligns with budget constraints while delivering maximum value.

The analysis should also factor in indirect benefits such as vendor reliability, technical support capabilities, and potential for future collaboration. Organizations must consider the total cost of ownership (TCO), including training requirements, operational efficiency improvements, and potential cost savings through bulk purchasing or long-term agreements. This comprehensive evaluation enables informed decision-making and helps establish a sustainable procurement framework that balances cost efficiency with quality and performance requirements.

Step 4: Tender Process Management

Digital Tender Management

Digital tender management has revolutionized construction procurement, transforming traditional paper-based processes into streamlined, efficient operations. By implementing modern procurement methods, organizations can significantly reduce administrative burden while enhancing transparency and compliance.

Cloud-based tender management platforms enable real-time collaboration between stakeholders, automated document version control, and secure bid submissions. These systems typically feature built-in analytics tools that help evaluate supplier responses objectively, comparing technical specifications and pricing structures across multiple bids simultaneously.

Key functionalities include automated supplier pre-qualification, integrated e-signature capabilities, and standardized templates for tender documentation. The system maintains a comprehensive audit trail, essential for regulatory compliance and process improvement analysis.

Industry leaders report up to 60% reduction in tender processing time and a 40% decrease in administrative costs through digital transformation. Advanced platforms also incorporate machine learning algorithms to identify potential risks and opportunities within supplier proposals, supporting more informed decision-making.

To maximize effectiveness, organizations should ensure proper staff training and establish clear digital workflows that align with existing procurement protocols. Regular system updates and maintenance are crucial for optimal performance and security.

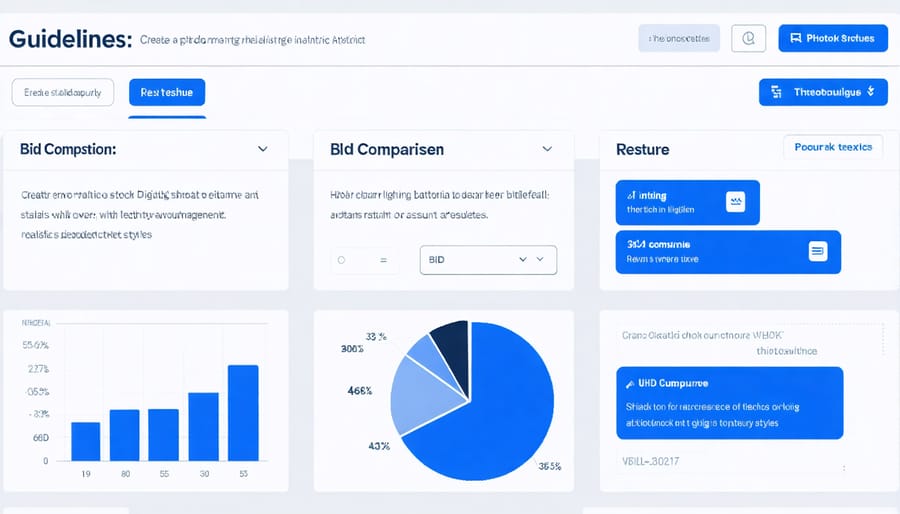

Bid Evaluation Methods

Once proposals are received, a systematic evaluation process begins using multiple assessment methods to ensure objective decision-making. The most common approach is the weighted criteria matrix, where key factors such as price, technical capability, experience, and project timeline are assigned specific weights based on their importance to the project.

Technical evaluation committees typically employ a two-envelope system, separating technical and financial proposals to prevent price bias during initial technical assessment. This allows for an unbiased evaluation of qualitative factors before considering cost implications.

Quantitative scoring systems, often on a scale of 1-10 or 1-100, are applied to each criterion, with clear scoring guidelines to maintain consistency across evaluators. Best value analysis combines both price and non-price factors to determine the most advantageous proposal for the project.

Life cycle cost analysis is particularly crucial for construction projects, considering not just initial costs but long-term operational and maintenance expenses. This comprehensive approach helps identify proposals that offer better value over the project’s entire lifespan.

The evaluation process must be thoroughly documented, with clear justification for scoring decisions, to ensure transparency and defend against potential bid protests. Regular calibration meetings between evaluators help maintain consistency and fairness throughout the assessment process.

Step 5: Contract Negotiation and Award

Key Contract Elements

A well-structured construction procurement contract must contain several critical elements to ensure project success and legal compliance. The scope of work should be clearly defined, including detailed specifications, deliverables, and quality standards. Payment terms need to outline the schedule, method, and conditions for disbursement, along with any retention provisions.

Timeline requirements must specify project milestones, completion dates, and potential penalties for delays. Risk allocation clauses should address liability distribution, insurance requirements, and indemnification provisions. The contract must also include clear terms for change orders, variations, and dispute resolution mechanisms.

Performance guarantees and warranties should protect the project owner’s interests while establishing reasonable contractor obligations. Health and safety requirements, environmental compliance, and local regulatory considerations must be explicitly stated. Termination clauses need to outline conditions and procedures for contract cessation, including force majeure events.

Additional essential elements include confidentiality agreements, intellectual property rights, and subcontractor management provisions. The contract should also specify documentation requirements, reporting procedures, and communication protocols between all parties involved in the procurement process.

Negotiation Tactics

Successful negotiation in construction procurement requires a strategic approach focused on achieving mutually beneficial outcomes. Begin by thoroughly understanding your leverage points, including market conditions, alternative suppliers, and project timelines. Establish clear minimum and maximum acceptable terms before entering negotiations, particularly regarding pricing, delivery schedules, and quality standards.

Employ the “bracket pricing” technique, where initial proposals include a reasonable buffer for negotiation while maintaining project viability. Document all discussed terms and maintain detailed records of agreements, changes, and concessions throughout the negotiation process. Consider incorporating value engineering proposals and bulk purchasing options as negotiation tools to achieve cost efficiencies.

Focus on developing long-term relationships rather than pursuing short-term gains. Address key contract elements such as payment terms, performance metrics, and risk allocation clearly and systematically. When dealing with preferred suppliers, emphasize partnership benefits while maintaining competitive tension. Utilize quantitative data and market research to support your position during negotiations, and always maintain professional communication channels, even during challenging discussions.

Remember that successful negotiation often involves finding creative solutions that address both parties’ core interests while ensuring project objectives are met within budget constraints.

Step 6: Implementation and Management

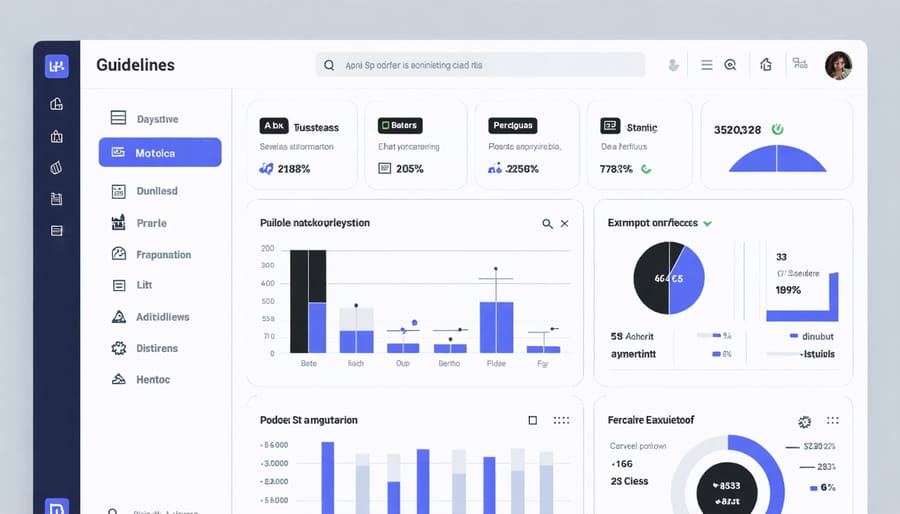

Performance Monitoring

Effective performance monitoring is crucial for maintaining procurement quality and supplier relationships. Key performance indicators (KPIs) should track delivery times, quality standards, cost adherence, and compliance with project specifications. Modern construction firms increasingly rely on AI-powered performance monitoring systems to collect and analyze supplier data in real-time.

Essential monitoring tools include supplier scorecards, quality control checklists, and deviation reports. Regular performance reviews should be conducted quarterly, focusing on metrics such as defect rates, response times to issues, and innovation contributions. Documentation of these evaluations helps identify trends and supports data-driven decision-making for future procurement strategies.

Construction firms should establish clear performance thresholds and corrective action protocols. This includes implementing automated alerts for delivery delays, quality issues, or cost overruns. Successful monitoring programs also incorporate feedback mechanisms for both suppliers and internal stakeholders, ensuring continuous improvement and maintaining strong working relationships throughout the project lifecycle.

Issue Resolution

Effective issue resolution in procurement requires a systematic approach to identify, document, and resolve challenges that arise during the process. Establishing a clear dispute resolution mechanism is crucial, starting with thorough documentation of all communications and decisions. When issues emerge, procurement teams should first attempt to resolve them through direct negotiation with suppliers, focusing on maintaining professional relationships while protecting project interests.

For complex disputes, implement a tiered resolution approach: begin with project-level discussions, escalate to senior management if necessary, and consider third-party mediation before pursuing legal action. Common procurement challenges include delivery delays, quality discrepancies, and cost variations. Address these proactively by including specific remediation clauses in contracts and maintaining open communication channels with suppliers.

Regular supplier performance reviews help identify potential issues before they escalate. When problems occur, document all corrective actions and their outcomes. This creates a valuable reference for future procurement activities and helps prevent similar issues. Consider establishing a procurement review board for major disputes, comprising key stakeholders who can make informed decisions based on project objectives and contractual obligations.

Step 7: Continuous Improvement

Continuous improvement in procurement processes is essential for maintaining competitive advantage and operational efficiency in construction projects. This final step involves systematic evaluation, feedback collection, and implementation of enhancement measures across all procurement activities.

Regular performance metrics analysis helps identify areas for improvement. Key indicators include supplier delivery times, cost variances, quality compliance rates, and procurement cycle duration. Construction firms should establish a structured review system that tracks these metrics against predetermined benchmarks.

Documentation of lessons learned from each procurement cycle is crucial. This includes maintaining detailed records of successful strategies, challenges encountered, and solutions implemented. These insights inform future procurement decisions and help prevent recurring issues.

Supplier relationship management plays a vital role in continuous improvement. Regular supplier performance evaluations, feedback sessions, and collaborative improvement initiatives can lead to enhanced service delivery and cost optimization. Construction companies should maintain open communication channels with key suppliers to address concerns promptly and explore innovation opportunities.

Technology adoption and process automation should be regularly assessed and updated. Modern procurement management systems, digital workflows, and data analytics tools can significantly improve efficiency and reduce manual errors.

Training and development of procurement staff ensures the team stays current with industry best practices and emerging technologies. Regular workshops, professional certifications, and knowledge-sharing sessions contribute to maintaining high performance standards and driving continuous improvement in the procurement process.

A well-structured procurement process is essential for successful construction project delivery. By following these seven steps systematically, organizations can significantly improve their procurement outcomes, reduce risks, and maximize value for money. The key to success lies in maintaining clear documentation, fostering strong supplier relationships, and ensuring thorough evaluation at each stage.

Implementation should be gradual and methodical, with proper training provided to team members and stakeholders. Organizations are advised to start with smaller projects to refine their process before scaling to larger initiatives. Digital procurement tools and management systems can streamline these steps, but they should complement rather than replace human oversight and decision-making.

Regular review and optimization of the procurement process is crucial. Monitor key performance indicators, gather feedback from team members and suppliers, and stay updated with industry best practices. Remember that procurement is not just about cost savings – it’s about building sustainable partnerships, ensuring quality deliverables, and supporting overall project success.

By embracing this structured approach to procurement, construction organizations can create a more efficient, transparent, and effective purchasing environment that delivers consistent results.