Monitor construction sites in real-time with advanced sensors, drones, and cameras integrated with cloud-based software platforms. Harness the power of the latest technologies like IoT, AI, and machine learning to gain unprecedented visibility into site activity, worker safety, equipment usage, and project progress. Streamline collaboration and decision-making with centralized dashboards that provide stakeholders with instant access to critical data and insights from any device, anywhere.

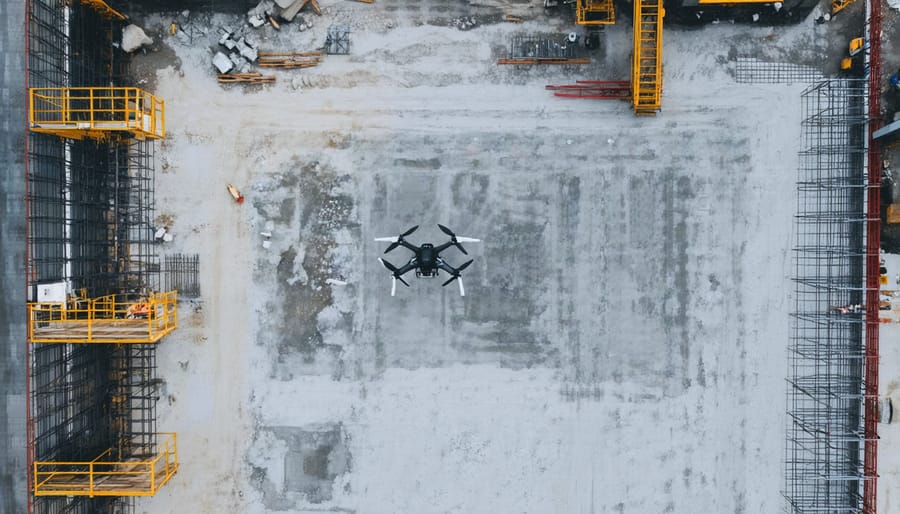

Drone Aerial Imaging

Automated Flight Paths

Automated flight paths revolutionize construction site monitoring by ensuring consistent and thorough imaging of the entire project area. Pre-programmed routes allow drones to capture high-resolution aerial photographs and videos in a systematic manner, eliminating the risk of missing critical details. This technology enables construction professionals to obtain a comprehensive overview of the site at regular intervals, facilitating progress tracking, issue identification, and timely decision-making. By leveraging automated flight paths, project managers can compare images over time to monitor changes, measure quantities, and verify compliance with plans. The consistent data collection also enhances collaboration among team members, as everyone has access to the same up-to-date visual information. Automated flight paths not only improve efficiency and accuracy in construction site monitoring but also reduce the need for manual inspections, ultimately saving time and resources while minimizing potential safety risks associated with on-site surveys.

Thermal Imaging Applications

Thermal imaging technology offers invaluable insights for construction site monitoring, enabling professionals to identify potential issues early and prevent costly repairs. By detecting temperature variations, thermal cameras can pinpoint areas of heat loss, indicating poor insulation or air leaks. This information allows contractors to optimize energy efficiency and maintain a comfortable environment within the structure. Moisture intrusion is another critical concern that thermal imaging can address. By identifying cold spots or temperature anomalies, professionals can locate water leaks, condensation buildup, or poor drainage before they cause significant damage to the building’s integrity. Furthermore, thermal imaging aids in detecting electrical issues, such as overheating components, loose connections, or imbalanced loads. By identifying these problems early, construction teams can prevent electrical fires, equipment failures, and potential safety hazards. Integrating thermal imaging into construction site monitoring practices ensures a proactive approach to building maintenance, energy efficiency, and occupant safety.

IoT Sensor Networks

Equipment Telematics

Equipment telematics revolutionizes construction site monitoring by leveraging advanced sensors to track vital metrics of machinery in real-time. GPS trackers provide precise location data, enabling project managers to optimize equipment allocation and prevent unauthorized use or theft. Usage sensors monitor operating hours, idle time, and productivity, facilitating data-driven decisions to maximize efficiency and profitability. Fuel sensors track consumption, identify inefficiencies, and help reduce waste. Predictive maintenance becomes possible as sensors detect early signs of wear, allowing timely repairs to minimize downtime and extend equipment lifespan. By integrating telematics data into centralized dashboards, construction professionals gain unparalleled insights into equipment performance, empowering them to make informed decisions, improve resource management, and enhance overall project success. As the technology continues to evolve, equipment telematics will undoubtedly become an indispensable tool for optimizing construction operations and staying competitive in an increasingly data-driven industry.

Environmental Monitoring

Effective environmental monitoring is crucial for maintaining optimal working conditions and ensuring the safety and well-being of construction workers. Advanced sensors can accurately measure key parameters such as temperature, humidity, noise levels, vibration, and air quality in real-time. By deploying a network of these sensors across the construction site, managers can gain valuable insights into the working environment and make informed decisions to mitigate potential risks.

Temperature and humidity sensors help prevent heat stress and cold-related illnesses by alerting workers when conditions become hazardous. Noise and vibration monitoring enable compliance with OSHA regulations, protecting workers from hearing damage and hand-arm vibration syndrome. Air quality sensors detect harmful pollutants, dust, and volatile organic compounds (VOCs), allowing for prompt action to maintain a healthy breathing environment. By leveraging environmental monitoring technology, construction professionals can create safer, more comfortable workspaces that boost productivity and minimize health risks for their teams.

Wearables for Worker Safety

Wearable technology is transforming worker safety on construction sites, offering real-time monitoring and alert capabilities. Smart hard hats, equipped with sensors and communication devices, provide a wealth of data to enhance safety measures. These innovative helmets can detect falls, monitor worker location, and even alert supervisors in case of an emergency. Safety vests, another cutting-edge wearable, feature built-in GPS tracking and proximity sensors to warn workers when they enter hazardous areas or are at risk of colliding with equipment. Wristbands, often integrated with biometric sensors, monitor vital signs such as heart rate and body temperature, alerting managers to potential health issues or fatigue. By leveraging these advanced wearables, construction companies can proactively identify and mitigate risks, improving worker safety and preventing accidents. Real-world case studies demonstrate the effectiveness of these technologies, with companies reporting significant reductions in incident rates and improved emergency response times. As the construction industry continues to embrace digital transformation, wearables for worker safety will undoubtedly become an essential component of comprehensive site monitoring strategies.

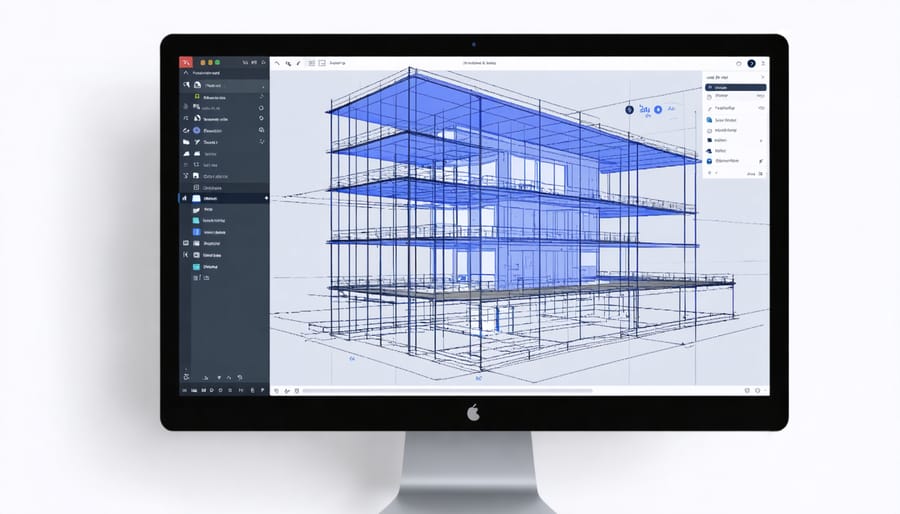

Digital Twin Technology

Digital twin technology is revolutionizing the way construction projects are designed, managed, and executed. By creating a virtual replica of the physical construction site, digital twins enable stakeholders to visualize, analyze, and optimize every aspect of the project lifecycle. This powerful tool integrates data from various sources, such as BIM models, IoT sensors, and drone imagery, to create a dynamic and interactive representation of the site.

One of the key benefits of Digital Twin Technology is enhanced design visualization. Architects, engineers, and project managers can explore the virtual site in real-time, assessing the impact of design changes and identifying potential issues before construction begins. This proactive approach minimizes costly rework and delays, ensuring that the final product meets the client’s expectations.

Digital twins also enable advanced clash detection, a critical process in construction site monitoring. By simulating the interaction between different building elements, such as mechanical, electrical, and plumbing systems, stakeholders can identify and resolve conflicts early in the design phase. This streamlined coordination reduces the risk of on-site clashes, which can lead to significant schedule and budget overruns.

Moreover, digital twins facilitate progress simulation, allowing project managers to compare the actual construction progress against the planned timeline. By integrating real-time data from the site, the virtual model can highlight deviations and potential bottlenecks, enabling proactive decision-making and resource allocation. This level of visibility and control is essential for keeping projects on track and within budget.

As construction projects become increasingly complex, digital twin technology offers a powerful solution for effective site monitoring and management. By leveraging the insights gained from virtual models, stakeholders can make informed decisions, mitigate risks, and deliver high-quality projects on time and within budget.

Cloud-Based Collaboration Platforms

The rise of cloud-based collaboration platforms has revolutionized the way construction projects are managed, enabling seamless data sharing and communication between the field and office. These powerful tools have become essential for large, complex projects with numerous stakeholders, as they facilitate real-time updates, document management, and decision-making. By centralizing all project information in a secure, accessible cloud environment, teams can work together more efficiently, regardless of their physical location.

Cloud collaboration platforms offer a wide range of features designed to streamline construction site monitoring. They allow users to upload and share plans, drawings, photos, and other critical documents, ensuring that everyone has access to the most up-to-date information. Real-time messaging and commenting capabilities foster open communication and quick problem-solving, while mobile apps enable field workers to easily capture and share site data, such as progress photos and safety observations.

For large projects with multiple stakeholders, cloud collaboration is crucial for keeping everyone informed and aligned. Owners, architects, engineers, contractors, and subcontractors can all access the same information, reducing the risk of miscommunication and delays. Automated workflows and notifications help ensure that tasks are completed on time and that any issues are promptly addressed. By providing a transparent, comprehensive view of the project, cloud platforms help stakeholders make informed decisions and work together more effectively.

As construction projects become increasingly complex and fast-paced, the adoption of cloud-based collaboration platforms will continue to grow. These tools not only improve efficiency and communication but also provide valuable data insights that can help optimize future projects. By embracing cloud collaboration, construction professionals can ensure that their projects stay on track, on budget, and deliver the best possible results for all stakeholders involved.

Conclusion

The future of construction site monitoring is undeniably exciting. As the industry continues to evolve and embrace digital transformation, these innovative technologies and techniques will become increasingly crucial for staying competitive. By leveraging drones, IoT sensors, AI-powered analytics, BIM integration, and wearable safety devices, construction professionals can unlock new levels of efficiency, safety, and collaboration on their projects.

Imagine a construction site where real-time data flows seamlessly between teams, enabling proactive decision-making and risk mitigation. Where safety hazards are identified and addressed before accidents occur, and where project progress is tracked with unparalleled accuracy. This is the transformative potential of advanced monitoring solutions.

For construction companies looking to stay ahead of the curve, now is the time to explore and adopt these game-changing innovations. By investing in cutting-edge monitoring technologies, firms can differentiate themselves in a crowded market, deliver projects faster and more cost-effectively, and ultimately, build a stronger reputation for excellence.

As the construction landscape continues to shift, those who embrace the power of data-driven monitoring will be well-positioned to thrive. The future of construction is here – and it’s time to seize the opportunity to revolutionize the way we build.