In the rapidly evolving construction industry, the terms “modular” and “prefab” homes often spark confusion among professionals and stakeholders alike. While both construction methodologies fall under the umbrella of off-site construction, they represent distinct approaches with significant technical and operational differences. Modular homes consist of complete three-dimensional units manufactured in controlled factory environments, while prefabricated homes encompass a broader spectrum of components produced off-site. This distinction carries substantial implications for project timelines, cost structures, and regulatory compliance.

Understanding these differences is crucial for construction professionals making strategic decisions about building methodologies. With the construction industry facing unprecedented labor shortages and increasing pressure to reduce project timelines, both modular and prefab construction offer compelling alternatives to traditional building methods. However, their application, benefits, and limitations vary significantly, impacting everything from initial design considerations to final installation procedures.

This technical analysis delves into the fundamental characteristics that distinguish modular from prefab construction, providing construction professionals with the critical insights needed to make informed decisions for their specific project requirements.

Understanding Modular Home Construction

The Modular Construction Process

The modular construction process follows a highly systematic approach that combines factory precision with on-site efficiency. Initially, architectural plans are converted into detailed manufacturing specifications, ensuring each module meets building codes and structural requirements. In climate-controlled factory settings, construction begins with the structural frame, typically using steel or engineered wood components.

Skilled technicians simultaneously work on multiple modules, installing electrical systems, plumbing, HVAC components, and interior finishes. This parallel processing, common in commercial modular construction applications, significantly reduces build time compared to traditional methods. Quality control inspections occur at each stage, with third-party verification ensuring compliance with local and national standards.

Once modules are approximately 80-95% complete, they’re carefully wrapped and transported to the construction site. Prior to module delivery, contractors prepare the foundation according to engineered specifications. Using precision crane operations, modules are sequentially placed and connected to create the complete structure. Final tasks include module-to-module connections, utility hook-ups, and exterior finishing work.

The entire process typically reduces construction time by 30-50% compared to traditional building methods. Weather-related delays are minimized since most construction occurs indoors, and material waste is significantly reduced through factory optimization and inventory control.

Quality Standards and Building Codes

Modular homes must adhere to stringent regulatory requirements and quality control measures that often exceed those of traditional site-built construction. These structures are governed by the International Building Code (IBC) and must comply with state and local building codes, including specific energy efficiency standards for the regions where they will be permanently installed.

The manufacturing process involves multiple inspection points throughout assembly, with third-party quality control professionals conducting thorough evaluations at each stage. These inspections are documented and certified, ensuring compliance with both federal and state regulations. Each module receives a certification label, indicating it meets or exceeds all applicable building codes.

Unlike some prefabricated structures, modular homes must satisfy requirements for wind loads, snow loads, and seismic conditions specific to their installation location. The engineering and design process incorporates these factors from the outset, resulting in structures that often demonstrate superior structural integrity compared to conventional construction.

Quality control in modular manufacturing facilities is particularly rigorous, with standardized processes, controlled environments, and precise material specifications. This systematic approach to construction quality helps eliminate common variables that can affect site-built homes, such as weather-related complications and inconsistent workmanship.

Prefabricated Home Essentials

Types of Prefabricated Homes

Prefabricated homes encompass several distinct categories, each with unique construction methodologies and applications. Panel-built homes utilize pre-constructed wall, floor, and roof sections manufactured in controlled factory environments. These panels, complete with insulation, electrical conduits, and exterior finishing, are transported to the site for rapid assembly, offering significant time savings compared to traditional construction methods.

Kit homes represent another significant category, providing pre-cut and pre-engineered building components that arrive on-site ready for assembly. These systems typically include detailed architectural plans and numbered components, allowing for systematic construction while maintaining quality control standards. Modern kit homes have evolved considerably from their historical counterparts, now incorporating advanced materials and energy-efficient designs.

Manufactured homes, formerly known as mobile homes, are built entirely in factory settings according to HUD code requirements. These units are transported complete to the installation site on a permanent chassis. While technically a type of prefabricated housing, manufactured homes follow different building codes and regulations than modular or other prefab varieties.

Container homes, utilizing modified shipping containers, have emerged as an innovative prefab solution. These structures can be extensively customized in factory settings, incorporating proper insulation, utilities, and interior finishes before transportation to the construction site. Their inherent structural integrity and standardized dimensions make them particularly suitable for modular configurations.

Understanding these distinctions is crucial for construction professionals when evaluating project requirements and determining the most appropriate prefabrication method for specific applications.

Manufacturing and Assembly Methods

The manufacturing processes for modular and prefab homes showcase distinct innovative construction methods that set them apart in production efficiency and quality control. Modular homes are manufactured in climate-controlled facilities where individual modules undergo comprehensive assembly line production. Each module is constructed to meet specific dimensional requirements, typically incorporating structural framework, electrical systems, plumbing, and interior finishes before transportation to the building site.

Prefab homes, while also manufactured off-site, may involve various components produced separately and assembled on-site according to predetermined specifications. These components can range from wall panels and roof trusses to pre-engineered building systems. The manufacturing process emphasizes precision cutting, standardized assembly procedures, and rigorous quality inspections throughout production.

On-site assembly requirements differ significantly between the two approaches. Modular homes arrive nearly complete, requiring crane installation to position and connect modules on the prepared foundation. Final assembly involves joining utilities, securing module connections, and completing exterior finishing work. Prefab homes typically demand more extensive on-site assembly, with components arriving in a logical sequence for systematic construction. This process requires skilled labor to ensure proper installation of prefabricated elements and integration of building systems according to manufacturer specifications and local building codes.

Key Differences Between Modular and Prefab Homes

Construction Methodology

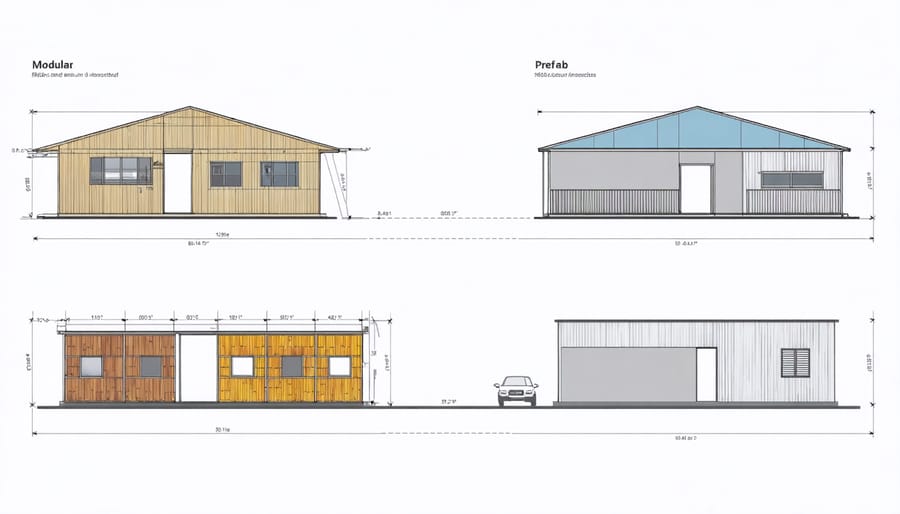

Modular and prefab homes employ distinct construction methodologies, though both prioritize off-site manufacturing processes. Modular construction involves creating complete volumetric units or modules in factory settings, with each module typically comprising 60-90% of the finished structure. These units are manufactured using precision equipment and include electrical, plumbing, and interior finishes before transportation to the site.

Prefabricated construction, while also factory-based, focuses on producing individual building components rather than complete modules. These components might include wall panels, roof trusses, or floor systems, which are then assembled on-site. The manufacturing process utilizes advanced CAD/CAM technology and automated production lines to ensure dimensional accuracy and quality control.

Both methods rely heavily on steel, engineered wood, and composite materials selected for their structural integrity and transportation durability. Quality control measures are more stringent in factory settings compared to traditional on-site construction, with multiple inspection points throughout the manufacturing process.

The assembly sequence differs significantly between the two approaches. Modular homes require careful crane operations to place and connect modules, typically completing structural assembly within days. Prefab homes involve more on-site assembly time, with components being systematically installed according to detailed technical specifications. Both methodologies must comply with local building codes and structural requirements, though the inspection process varies based on the construction approach.

Customization Options

While both modular and prefab homes offer alternatives to traditional construction, their customization capabilities differ significantly. Modular homes typically provide more extensive design flexibility, allowing for architectural variations and structural modifications within the constraints of transportation and assembly requirements. These units can accommodate diverse floor plans, multiple stories, and various architectural styles while maintaining manufacturing efficiency.

Prefabricated homes, by comparison, often come with predetermined design options and standardized components. However, this standardization enables cost-effective customization through interchangeable elements and finish selections. Modern prefab systems have evolved to offer semi-custom solutions, allowing clients to modify specific aspects of the design while retaining the benefits of factory-controlled production.

Both construction methods support material customization, including exterior cladding, roofing systems, and interior finishes. Modular construction typically offers greater flexibility in room configurations and spatial arrangements, while prefab systems excel in standardized customization options that can be efficiently implemented during manufacturing.

Engineering considerations play a crucial role in customization possibilities. Modular units must account for transportation limitations and structural integrity during assembly, which can impact design choices. Prefab systems, particularly panelized construction, may offer more latitude in certain architectural elements but require careful consideration of connection details and assembly sequences.

Industry professionals should evaluate project requirements, site conditions, and client preferences when determining which approach better serves their customization needs. Both methods can achieve high-quality, personalized results when properly engineered and executed.

Cost and Timeline Considerations

When evaluating modular and prefab homes from a financial perspective, several key factors influence both initial costs and long-term value. Modular homes typically require a 10-15% lower initial investment compared to traditional construction, while prefab homes can offer savings of 5-10%. These cost differentials stem from streamlined manufacturing processes and construction cost optimization through standardized components.

Timeline considerations also significantly impact project economics. Modular homes generally achieve 30-50% faster completion times than traditional builds, with a typical 12-16 week manufacturing period followed by 2-4 weeks of on-site assembly. Prefab homes, depending on complexity and customization levels, usually require 8-12 weeks for component manufacturing and 4-6 weeks for on-site assembly.

Labor costs vary significantly between the two approaches. Modular construction typically reduces labor expenses by 20-30% due to factory-controlled environments and specialized workforce efficiency. Prefab construction offers moderate labor savings of 15-25%, primarily through reduced on-site work requirements.

Additional cost factors include transportation logistics, crane requirements for module placement, and site preparation. Modular homes may incur higher transportation costs due to complete unit shipping, while prefab components often allow for more efficient logistics planning. Both methods require careful consideration of site accessibility and preparation costs, which can impact overall project budgets.

Making the Right Choice for Your Project

When selecting between modular and prefab construction for your project, several critical factors must be considered to ensure optimal outcomes. First, evaluate your project’s timeline requirements. Modular construction typically offers faster completion times due to its standardized manufacturing process and parallel site preparation capabilities, potentially reducing overall project duration by 30-50% compared to traditional construction methods.

Budget considerations play a crucial role in the decision-making process. While both methods generally offer cost savings over traditional construction, modular homes often require higher upfront costs due to their complete factory assembly. Prefab components may offer more flexibility in managing costs, as you can selectively choose which elements to prefabricate based on budget constraints.

Site accessibility and location significantly impact your choice. Modular units require careful consideration of transportation routes and crane access for installation. Projects in remote or challenging locations might benefit more from prefab components, which offer greater flexibility in transportation and assembly methods.

Design complexity and customization needs should also guide your decision. Modular construction excels in projects requiring repetitive elements and standardized designs, making it ideal for multi-unit developments. Prefab construction offers more design flexibility and can better accommodate unique architectural features or site-specific requirements.

Consider your project’s long-term objectives as well. Modular buildings typically offer superior quality control due to factory conditions but may have limitations for future modifications. Prefab construction can provide more adaptability for future changes while still maintaining quality standards.

Consulting with experienced manufacturers and contractors in both methods is essential for making an informed decision aligned with your specific project requirements and constraints.

While modular and prefab homes share common roots in off-site construction, they represent distinct approaches to modern building methodology. The key differentiator lies in their scope and assembly process: modular construction involves complete volumetric units, while prefab encompasses a broader spectrum of pre-manufactured components. This distinction has significant implications for project planning, cost considerations, and construction timelines.

Looking ahead, both construction methods are poised to play crucial roles in addressing housing demands and sustainability goals. The modular sector is evolving toward increasingly sophisticated factory automation and quality control systems, while prefab technologies continue to expand their range of applications and materials. Industry trends suggest a future where these methods may converge in hybrid approaches, combining the best aspects of both systems.

For construction professionals and stakeholders, understanding these differences is crucial for making informed project decisions. As technology advances and market demands evolve, both modular and prefab construction will likely continue to innovate, offering increasingly efficient and sustainable solutions for the built environment. The key to success lies in selecting the appropriate method based on specific project requirements, site conditions, and desired outcomes.