Understand the critical role R-value plays in your building’s energy efficiency, comfort, and long-term savings. Innovative projects like Starbucks’ energy-efficient modular store showcase the power of high-performance insulation. Invest the time to thoroughly evaluate R-values for walls, roofs, floors, and windows – small improvements can yield substantial energy savings over your building’s lifespan. Look beyond the numbers and consider real-world performance factors like installation quality, air leakage, and moisture control to maximize the effectiveness of your insulation system. Partner with experienced professionals who can guide material selection and ensure proper installation techniques for optimal results. By prioritizing R-value and taking a holistic approach to building envelope design, you’ll create structures that stand the test of time while minimizing environmental impact and operating costs.

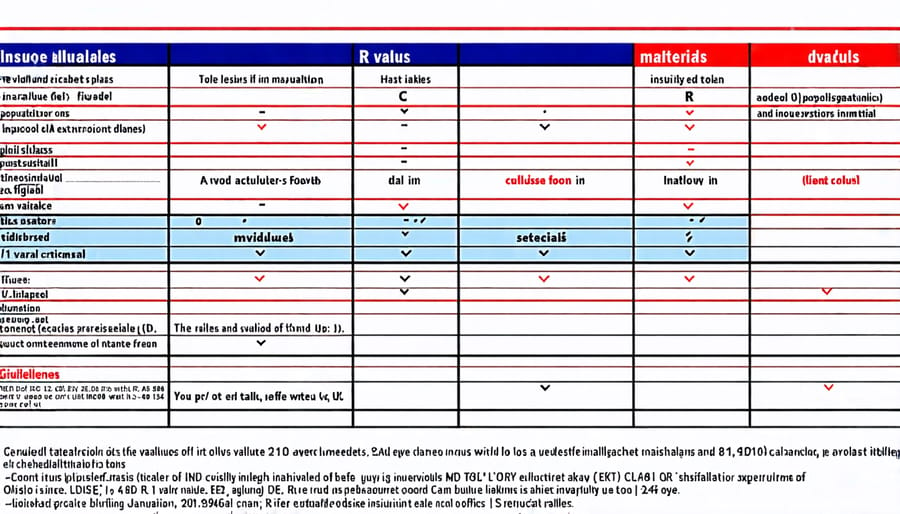

Common Building Materials and Their R-Values

Insulation Materials

Several popular insulation materials are commonly used in construction, each with its own R-value per inch. Fiberglass, a widely used insulation material, has an R-value ranging from 2.2 to 2.7 per inch, depending on the density and thickness of the batts or rolls. Cellulose insulation, made from recycled paper products, offers an R-value of approximately 3.5 per inch when properly installed. Spray foam insulation, such as closed-cell polyurethane, provides a higher R-value of around 6.5 per inch, making it an excellent choice for areas with limited space. Rigid foam board insulation, like extruded polystyrene (XPS), has an R-value of about 5 per inch, while expanded polystyrene (EPS) has an R-value of approximately 4 per inch. Other materials, such as mineral wool and denim insulation, offer R-values ranging from 3.0 to 3.7 per inch. It’s important to note that the overall R-value of an insulated wall, roof, or floor assembly depends not only on the insulation material but also on factors like the thickness of the insulation, proper installation, and the presence of thermal bridges. Consulting with insulation experts and referring to manufacturer specifications can help in selecting the most appropriate insulation material for a given project.

Structural Materials

Structural materials play a crucial role in determining the overall thermal performance of a building. Wood, a common structural material, has a relatively low R-value per inch, ranging from R-1.41 for softwoods to R-1.61 for hardwoods. However, wood’s low thermal conductivity makes it an effective insulator when used in thick layers. Concrete, another widely used structural material, has an R-value of approximately R-0.08 per inch, making it a poor insulator on its own. To improve its thermal performance, concrete can be combined with insulating materials or used in insulated concrete forms (ICFs). Brick, a traditional building material, has an R-value of about R-0.20 per inch, which is slightly better than concrete but still relatively low. Structural insulated panels (SIPs), which consist of an insulating foam core sandwiched between two structural facings, offer higher R-values, ranging from R-4 to R-6.5 per inch, depending on the type of insulation used. Understanding the R-values of structural materials helps construction professionals make informed decisions when designing energy-efficient buildings.

Windows and Doors

Windows and doors play a crucial role in a building’s energy efficiency, and their R-values can vary significantly depending on the type and design. Single-pane windows have the lowest R-value, typically ranging from 0.85 to 1.0, offering minimal insulation. Double-pane windows, which feature two layers of glass with an air or gas-filled space between them, provide better insulation with R-values between 1.5 and 3.0. Insulated windows, such as those with triple panes or low-emissivity (low-E) coatings, can achieve even higher R-values, ranging from 3.0 to 5.0 or more. When selecting windows and doors, it’s essential to consider factors such as frame materials, spacer types, and gas fills, as they all contribute to the overall R-value. Properly installed, high-performance windows and doors can significantly reduce heat transfer, improve comfort, and lower energy costs in both residential and commercial buildings.

Factors Affecting R-Value Performance

Installation Quality

Proper installation is crucial for building materials to achieve their rated R-values. Even the most efficient insulation can fail to perform as expected if not installed correctly. Common installation issues include gaps, compression, and improper sealing around edges and penetrations. These problems allow heat to bypass the insulation, reducing its effectiveness. Moisture intrusion due to poor sealing can also degrade the insulation’s performance over time. Improper installation of radiant barriers, such as incorrect spacing or sagging, can significantly reduce their reflective properties and overall R-value contribution. To ensure optimal performance, it is essential to follow manufacturer guidelines and industry best practices during installation. This includes proper sizing, spacing, and sealing of materials, as well as quality control measures to verify the integrity of the installation. By prioritizing installation quality, construction professionals can maximize the energy efficiency benefits of the building materials they select.

Age and Degradation

Over time, the R-value of building materials can decrease due to various factors such as material degradation and settling. Insulation materials like fiberglass, cellulose, and foam may compress or shift, reducing their effectiveness in resisting heat flow. Moisture intrusion can also degrade insulation performance, particularly in materials like fiberglass and cellulose. As building materials age and are exposed to temperature fluctuations, UV radiation, and other environmental stressors, their ability to maintain their initial R-value may diminish. This degradation can lead to increased energy consumption and reduced thermal comfort within the building. To mitigate the effects of age and degradation, it is essential to select high-quality, durable materials and ensure proper installation techniques are followed. Regular inspections and maintenance can also help identify and address any issues that may compromise the insulation’s performance over time.

Climate and Moisture

Climate and moisture conditions significantly impact the effectiveness of R-values in building materials. In humid regions, moisture can penetrate insulation, reducing its thermal resistance. Conversely, in dry climates, materials may perform closer to their rated R-values. Temperature extremes also affect R-value performance; some materials lose insulating properties in freezing conditions, while others are more stable. Proper installation and moisture control are crucial for maintaining R-value effectiveness. Techniques such as air sealing, vapor barriers, and ventilation help prevent moisture intrusion and maintain optimal thermal performance. Consulting with local experts and considering climate-specific strategies are essential for ensuring the long-term effectiveness of insulation materials in any given environment. By understanding the relationship between climate, moisture, and R-values, construction professionals can make informed decisions to maximize energy efficiency in their projects.

Optimizing R-Value in Your Projects

Conduct a Thorough Energy Audit

To optimize energy efficiency in your building, conducting a thorough energy audit is crucial. This process involves assessing the current energy performance of the structure, identifying areas of weakness, and pinpointing opportunities for improvement. By analyzing factors such as insulation levels, air leakage, and HVAC system efficiency, an energy audit provides valuable insights into where energy is being wasted and how it can be conserved. The findings from an energy audit serve as a roadmap for implementing targeted upgrades and retrofits that enhance the building’s overall energy performance, ultimately leading to reduced energy consumption, lower utility costs, and a more sustainable built environment.

Select Materials Based on Climate

When selecting building materials for your project, it’s crucial to consider the climate zone in which the structure will be located. Different regions have varying temperature ranges, humidity levels, and weather patterns that can significantly impact the effectiveness of insulation materials. Consult local building codes and energy efficiency guidelines to determine the recommended R-values for your specific climate zone. For example, homes in colder regions may require higher R-values to maintain a comfortable indoor environment and minimize heat loss. In contrast, homes in warmer climates may prioritize materials with better resistance to heat transfer. By choosing materials with R-values optimized for your climate, you can create an ultra-efficient home that reduces energy consumption and maintains a comfortable living space year-round.

Prioritize Proper Installation

Proper installation is crucial for ensuring that building materials achieve their intended R-value and energy efficiency. Failing to follow manufacturer guidelines and industry best practices can lead to suboptimal performance, reduced energy savings, and potential structural issues. Construction professionals must prioritize meticulous installation techniques, paying close attention to details such as sealing gaps, minimizing thermal bridging, and ensuring consistent coverage. Regularly training and updating the knowledge of installation teams is essential for maintaining high standards and staying current with advancements in sustainable construction practices. By prioritizing proper installation, construction projects can maximize the benefits of high R-value materials and contribute to more energy-efficient, comfortable, and durable buildings.