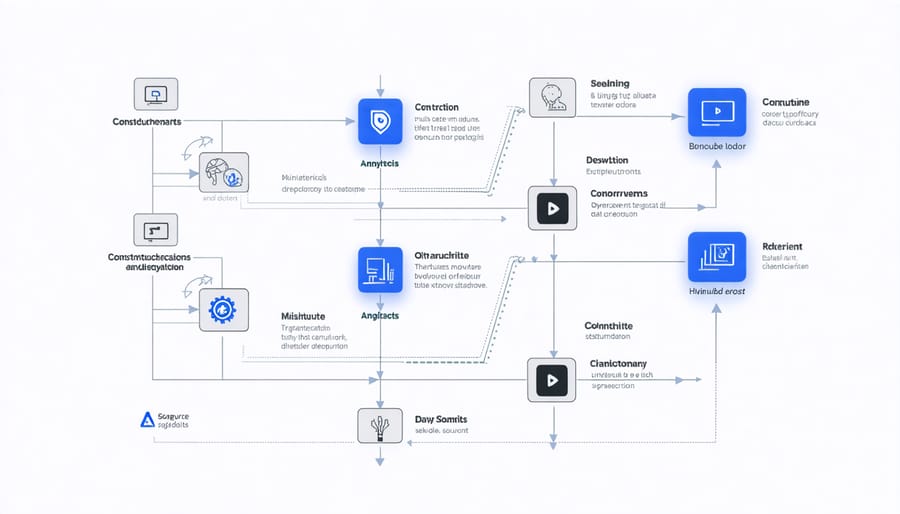

Predictive analytics and artificial intelligence intersect at a critical junction in modern construction technology, transforming how industry leaders approach project planning and digital procurement solutions. While both technologies leverage data-driven insights, predictive analytics represents a specialized subset of AI capabilities, focusing specifically on forecasting future outcomes based on historical patterns and real-time data analysis. For construction professionals managing complex projects, understanding this distinction is crucial: predictive analytics employs machine learning algorithms and statistical modeling to anticipate project delays, optimize resource allocation, and enhance procurement strategies, while AI encompasses a broader spectrum of intelligent automation and decision-making capabilities. Recent industry implementations have demonstrated that predictive analytics serves as both a foundational element and practical application of AI technology, delivering measurable improvements in project efficiency and risk management across the construction sector. This synergy between predictive analytics and AI continues to reshape how construction firms approach project planning, bid management, and supply chain optimization.

The AI Foundation of Modern Predictive Analytics

Machine Learning Algorithms in Construction Data Analysis

Several machine learning algorithms have proven particularly effective in construction data analysis and procurement prediction. Random Forest algorithms excel at analyzing historical project data, accurately predicting cost variations and timeline deviations by evaluating multiple decision trees simultaneously. This approach has shown remarkable accuracy in projects where numerous variables, from material costs to weather conditions, influence outcomes.

Support Vector Machines (SVM) have demonstrated success in classifying procurement risks and predicting supplier performance. Construction firms utilize SVM algorithms to analyze supplier reliability metrics, delivery times, and quality indicators, enabling more informed vendor selection decisions.

Neural Networks, particularly Deep Learning models, process complex patterns in construction bid data, helping organizations optimize their bidding strategies. These systems can analyze thousands of historical bids, identifying subtle patterns that influence successful contract awards.

Gradient Boosting algorithms, such as XGBoost, have become invaluable for cost estimation and resource allocation. These models excel at handling the diverse data types common in construction projects, from numerical measurements to categorical variables like material types and regulatory requirements.

K-Nearest Neighbors (KNN) algorithms assist in project classification and similarity analysis, helping firms identify comparable past projects to inform current decision-making. This approach is particularly useful when evaluating new projects against historical performance data.

These algorithms, when properly implemented with clean, relevant data, typically achieve prediction accuracies between 80-95% in construction applications, significantly reducing procurement risks and improving project outcomes.

Neural Networks and Deep Learning Applications

Neural networks and deep learning represent the cutting edge of predictive analytics in construction, enabling more sophisticated analysis than traditional statistical methods. These AI technologies excel at identifying complex patterns in construction data, from material costs and supplier performance to project timelines and risk factors.

In modern construction procurement, deep learning models can process vast amounts of historical project data, including bid documents, contractor performance records, and market conditions. These systems learn from past procurement decisions and their outcomes, continuously improving their predictive accuracy. For example, a neural network can analyze thousands of past projects to predict potential cost overruns or identify optimal supplier combinations for specific project types.

Multi-layer neural networks are particularly effective in handling the multifaceted nature of construction projects. They can simultaneously process numerous variables such as weather patterns, material availability, labor costs, and market fluctuations to generate accurate procurement recommendations. This capability extends to predicting supplier reliability, material price trends, and potential project delays.

Construction firms implementing these advanced AI systems report significant improvements in procurement efficiency. Neural networks can detect subtle correlations that human analysts might miss, such as the relationship between specific supplier combinations and project success rates. This deep learning approach enables more precise risk assessment and better-informed decision-making in procurement strategies.

Real-World Applications in Construction Procurement

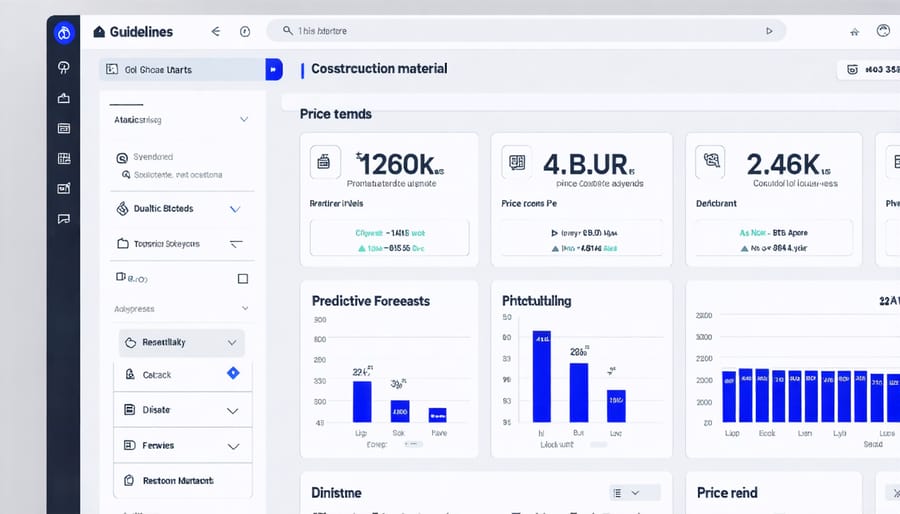

Material Cost Forecasting

In today’s volatile construction market, AI-powered predictive analytics has revolutionized material cost forecasting by analyzing complex data patterns to anticipate price fluctuations. These sophisticated systems integrate multiple data sources, including historical pricing data, market trends, global economic indicators, and supply chain dynamics to generate accurate cost predictions.

Construction companies leveraging these AI solutions can optimize their purchasing strategies by identifying the ideal timing for bulk material orders. The technology works in conjunction with smart inventory management systems to maintain optimal stock levels while considering predicted price changes.

Machine learning algorithms continuously analyze market signals, such as commodity prices, transportation costs, and supplier capacity constraints, to forecast potential price variations months in advance. This predictive capability enables procurement teams to lock in favorable prices and establish strategic supplier relationships based on data-driven insights.

Recent implementations have shown that companies using AI-driven material cost forecasting typically achieve 12-15% cost savings on major purchases. The system’s ability to detect early warning signs of price increases allows organizations to adjust their procurement schedules and negotiate better terms with suppliers proactively.

For maximum effectiveness, these predictive models are regularly calibrated with real-time market data and actual purchase outcomes, ensuring increasingly accurate forecasts over time. This continuous learning process helps construction firms maintain competitive advantages while effectively managing their material costs.

Supplier Performance Prediction

In today’s data-driven construction landscape, AI-powered predictive analytics is transforming how organizations evaluate and forecast supplier performance. By integrating with modern digital procurement tools, these systems analyze historical supplier data, market conditions, and real-time performance metrics to generate accurate predictions about supplier reliability.

The AI algorithms examine multiple factors simultaneously, including delivery times, quality consistency, pricing stability, and compliance records. This comprehensive analysis enables construction firms to identify potential risks before they materialize, helping project managers make informed decisions about supplier selection and relationship management.

For instance, leading construction firms are using predictive analytics to forecast supplier financial stability by analyzing payment patterns, market indicators, and industry trends. The system can flag potential issues such as impending supply chain disruptions or financial distress, allowing procurement teams to implement preventive measures proactively.

These AI-driven predictions have demonstrated remarkable accuracy, with some systems achieving 85-90% accuracy in forecasting supplier-related disruptions. This capability has proven particularly valuable during market volatility, helping construction companies maintain project timelines and budget controls through informed supplier management strategies.

The technology also facilitates continuous performance monitoring, automatically adjusting predictions based on new data and changing circumstances, ensuring that supplier assessment remains current and reliable throughout the project lifecycle.

Risk Assessment and Mitigation

AI-powered predictive analytics has revolutionized risk assessment in construction procurement by enabling more accurate identification and mitigation of potential threats. Using historical project data, market trends, and supplier performance metrics, these systems can forecast various risk factors with remarkable precision.

Machine learning algorithms analyze patterns in supplier behavior, market volatility, and project outcomes to generate risk scores for different procurement decisions. This automated assessment helps construction managers identify high-risk suppliers, anticipate material shortages, and predict potential cost overruns before they occur.

A notable example is how leading construction firms use predictive models to evaluate supplier reliability. These systems analyze factors such as past delivery times, quality consistency, financial stability, and market conditions to calculate risk probabilities. This comprehensive analysis enables procurement teams to make data-driven decisions and implement preventive measures proactively.

Risk mitigation strategies informed by predictive analytics typically include:

– Diversifying supplier networks based on risk profiles

– Implementing early warning systems for supply chain disruptions

– Adjusting procurement schedules to account for predicted delays

– Establishing contingency plans based on probability scenarios

The integration of real-time data feeds further enhances risk assessment capabilities, allowing construction firms to adapt their procurement strategies dynamically. This proactive approach has demonstrated significant improvements in project outcomes, with some organizations reporting up to 30% reduction in procurement-related delays and cost overruns.

Implementation Challenges and Solutions

Data Quality and Integration

The foundation of successful predictive analytics in construction lies in the quality and integration of data sources. Construction projects generate vast amounts of information from multiple channels, including BIM models, project management software, IoT sensors, and historical records. However, this data often exists in silos, making it challenging to create accurate predictive models.

To ensure effective implementation, organizations must first establish robust data collection protocols and standardization practices. This includes cleaning historical data to remove inconsistencies, implementing validation checks for new data entries, and creating unified data formats across different systems. Construction firms should particularly focus on standardizing cost data, schedule information, and performance metrics.

Integration challenges often arise when combining data from various sources. For instance, merging weather data with construction progress reports, or connecting supplier information with project timelines requires careful consideration of data relationships and dependencies. Modern construction management platforms are addressing these challenges through API integrations and automated data validation tools.

Data quality issues can significantly impact prediction accuracy. Common problems include missing values in historical records, inconsistent measurement units, and outdated information. Successful organizations implement continuous data monitoring systems and regular audits to maintain data integrity. They also invest in training staff to properly input and manage project data, understanding that quality predictions depend on quality inputs.

Team Training and Adoption

Successful implementation of predictive analytics requires a structured approach to team training and user adoption. Begin by identifying key stakeholders across different departments, including project managers, estimators, and procurement specialists. Develop a phased training program that starts with fundamental concepts and gradually progresses to advanced applications.

Create dedicated implementation teams comprising both technical experts and end-users. These cross-functional teams can better address specific departmental needs while ensuring consistent adoption throughout the organization. Schedule regular workshops focusing on practical applications, using real project data to demonstrate immediate value.

Documentation and standard operating procedures should be readily available, including step-by-step guides and troubleshooting resources. Establish a mentorship program where experienced users can guide newcomers, fostering knowledge sharing and building confidence in using predictive analytics tools.

Monitor adoption metrics and gather feedback regularly to identify barriers and resistance points. Address concerns promptly and showcase early wins to maintain momentum. Consider implementing a certification program to recognize proficiency levels and incentivize continuous learning.

Support ongoing education through lunch-and-learn sessions, online training modules, and access to external resources. Create a feedback loop where users can suggest improvements and share success stories, building a culture of data-driven decision-making. Remember that successful adoption is an iterative process requiring sustained commitment and regular reinforcement of best practices.

Future Trends and Opportunities

The future of AI-driven predictive analytics in construction procurement promises transformative developments that will reshape how projects are planned, executed, and managed. Integration with emerging technologies, particularly blockchain in construction supply chains, will enable unprecedented levels of transparency and efficiency in procurement processes.

Machine learning algorithms are becoming increasingly sophisticated, with the ability to process vast amounts of historical project data, market trends, and real-time information to make more accurate predictions. Industry experts anticipate that by 2025, predictive analytics systems will be capable of automatically adjusting procurement strategies based on real-time market conditions and project requirements.

The emergence of digital twins and IoT sensors will provide richer data streams for predictive models, enabling more precise forecasting of material needs and supplier performance. These advances will lead to truly automated procurement systems that can anticipate supply chain disruptions and automatically initiate contingency plans.

Another significant trend is the development of collaborative AI platforms that enable multiple stakeholders to share data and insights securely. These platforms will facilitate better coordination between contractors, suppliers, and project managers, reducing delays and optimizing resource allocation.

As sustainable construction practices become increasingly important, predictive analytics will play a crucial role in identifying eco-friendly materials and suppliers, while optimizing transportation routes to reduce carbon footprints. The integration of environmental impact data into procurement decisions will become standard practice, driven by both regulatory requirements and market demands.

Predictive analytics undeniably represents a crucial component of AI technology in modern construction practices. Through our exploration, we’ve seen how these tools leverage historical data, machine learning algorithms, and real-time insights to enhance decision-making across procurement and project management processes.

For construction professionals looking to implement these solutions, start by identifying specific pain points in your procurement workflow that could benefit from data-driven predictions. Focus on gathering quality historical data and ensuring your team has the necessary training to interpret and act on analytical insights. Remember that successful implementation requires a balanced approach – combining technological capabilities with human expertise and industry knowledge.

The future of construction procurement lies in the intelligent application of predictive analytics and AI. By embracing these technologies while maintaining realistic expectations about their capabilities and limitations, construction companies can achieve significant improvements in cost management, risk assessment, and project outcomes. The key is to view predictive analytics not as a replacement for human judgment, but as a powerful tool that enhances our decision-making capabilities and drives operational excellence in construction procurement.