Heat pumps represent a transformative shift in modern HVAC technology, delivering up to 300% greater efficiency compared to traditional heating and cooling systems. As global energy costs surge and environmental regulations tighten, these advanced systems have emerged as cornerstone components of energy efficient home solutions and commercial building designs. By extracting and transferring heat rather than generating it through combustion, heat pumps dramatically reduce operational costs while maintaining precise temperature control across diverse climate conditions.

Recent technological breakthroughs in variable-speed compressors and enhanced refrigerant designs have pushed coefficient of performance (COP) ratings beyond 4.0, establishing new benchmarks for sustainable heating and cooling infrastructure. For construction professionals and facility managers, this represents an unprecedented opportunity to achieve both environmental compliance and substantial long-term cost savings through strategic HVAC system optimization.

This comprehensive analysis explores cutting-edge heat pump technologies, implementation strategies, and real-world performance metrics that are reshaping the building efficiency landscape.

How Modern Heat Pumps Transform Energy Efficiency

Advanced Heat Pump Technology Explained

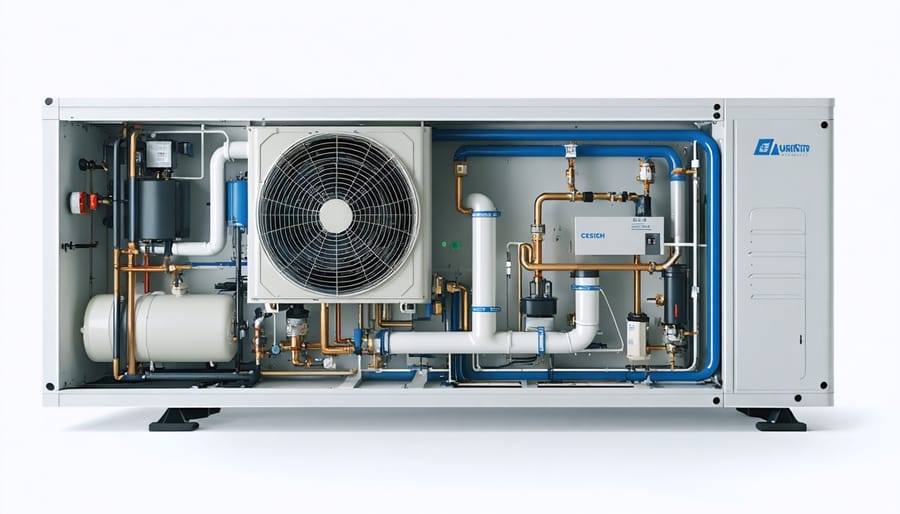

Modern heat pumps employ a sophisticated system of components working in harmony to achieve optimal thermal transfer efficiency. At the core of the system lies the vapor-compression cycle, which consists of four primary components: the compressor, condenser, expansion valve, and evaporator. The compressor pressurizes the refrigerant, raising its temperature and energy state, while the condenser facilitates heat exchange with the surrounding environment.

Variable-speed compressors represent a significant advancement in heat pump technology, allowing systems to modulate output based on demand rather than operating in simple on/off cycles. This capability enables efficiency ratings exceeding 300% in ideal conditions, meaning for every unit of electricity consumed, three units of heat energy are transferred.

The integration of electronic expansion valves (EEVs) provides precise control over refrigerant flow, optimizing system performance across varying conditions. Modern heat pumps also incorporate advanced defrost cycles and auxiliary heating elements to maintain efficiency in extreme temperatures.

Smart controls and monitoring systems enhance operation through real-time adjustment of parameters such as fan speeds, compressor frequency, and refrigerant flow rates. These systems utilize sophisticated algorithms to predict heating and cooling demands, ensuring optimal performance while minimizing energy consumption.

Recent innovations include enhanced vapor injection technology and scroll compressor designs that significantly improve cold-weather performance, enabling effective operation in temperatures as low as -15°F (-26°C).

Energy Savings: The Numbers Behind Heat Pump Efficiency

Recent studies demonstrate that modern heat pumps achieve remarkable efficiency ratings, with COPs (Coefficient of Performance) ranging from 3.0 to 5.0, meaning they produce 3-5 units of heat energy for every unit of electricity consumed. This translates to operational efficiency rates of 300-500%, significantly outperforming traditional heating systems that typically operate at 95-98% efficiency.

Analysis of real-world implementations shows that commercial buildings utilizing heat pumps report average energy savings of 25-50% compared to conventional HVAC systems. A comprehensive study across 100 commercial properties revealed annual energy cost reductions averaging $2.58 per square foot, with peak savings reaching $4.00 per square foot in optimal conditions.

In cold climates, advanced cold-climate heat pumps maintain efficiency even at temperatures as low as -13°F (-25°C), achieving COPs of 2.0 or higher. This performance results in typical annual heating cost reductions of 30-40% compared to oil-based systems, and 60-70% compared to electric resistance heating.

Initial investment costs are offset by operational savings, with most commercial installations reaching ROI within 3-5 years. Department of Energy data indicates that heat pump systems reduce greenhouse gas emissions by 50-60% compared to fossil fuel heating systems, while reducing annual operating costs by $2,000-$3,000 for average commercial facilities of 10,000 square feet.

Latest Innovations in Heat Pump Systems

Smart Integration and Control Systems

Modern heat pump systems are increasingly incorporating advanced smart building technology to optimize performance and enhance energy efficiency. These intelligent control systems utilize IoT sensors and sophisticated algorithms to monitor environmental conditions, occupancy patterns, and system performance in real-time.

Integration with building management systems (BMS) allows heat pumps to respond dynamically to changing conditions. Advanced controllers can anticipate heating and cooling demands based on weather forecasts, historical usage patterns, and real-time energy pricing, automatically adjusting operation parameters for maximum efficiency.

Key features include remote monitoring capabilities, predictive maintenance alerts, and automated performance optimization. Multi-zone control systems enable precise temperature management across different building areas, while smart scheduling functions ensure optimal operation during peak and off-peak hours.

Industry data shows that implementing these intelligent control systems can reduce energy consumption by an additional 15-25% compared to standard heat pump installations. The integration of machine learning algorithms continues to improve system efficiency over time, making smart controls an essential component of modern heat pump installations.

Variable-Speed Technology

Variable-speed technology represents a significant advancement in heat pump efficiency, utilizing electronically commutated motors (ECMs) and sophisticated inverter-driven compressors to optimize performance. Unlike traditional single-speed systems, these advanced motors can modulate their output between 25% and 100% capacity, precisely matching the building’s heating and cooling demands.

The efficiency gains are substantial, with variable-speed heat pumps achieving SEER ratings up to 20 and HSPF values exceeding 10. This translates to approximately 30-40% energy savings compared to conventional fixed-speed units. The precise speed control allows for longer running cycles at lower speeds, which not only reduces energy consumption but also provides superior temperature control and dehumidification.

These systems excel in partial-load conditions, which represent about 80% of typical operating time. The ability to run at reduced speeds minimizes the energy-intensive start-stop cycles common in traditional systems. Advanced motor controls also enable soft-start capabilities, reducing mechanical stress and electrical demand spikes during startup, while sophisticated algorithms continuously optimize performance based on real-time conditions and load requirements.

Cold Climate Performance Improvements

Recent technological breakthroughs have significantly enhanced heat pump performance in cold climates, with advanced models now operating efficiently at temperatures as low as -25°F (-32°C). Variable-speed compressor technology enables systems to adjust output capacity based on demand, maintaining consistent heating even in extreme conditions. Enhanced vapor injection systems increase heating capacity and coefficient of performance (COP) by up to 25% compared to traditional heat pumps.

Modern cold climate heat pumps incorporate optimized defrost cycles, reducing energy waste and system downtime during winter operation. Advanced electronic expansion valves provide precise refrigerant control, while improved heat exchanger designs maximize heat transfer efficiency at low temperatures. Flash tank economizer systems, now standard in premium models, help maintain system performance by managing refrigerant pressure more effectively.

Field studies demonstrate these improvements deliver reliable heating in northern regions previously considered unsuitable for heat pump technology. For example, installations in Minnesota and Maine report maintaining indoor temperatures above 70°F (21°C) even during sustained sub-zero conditions, while achieving seasonal COPs above 2.5 – significantly outperforming conventional electric heating systems.

Implementation and ROI Analysis

Installation Best Practices

Proper installation is crucial for maximizing heat pump efficiency and longevity. Begin with a comprehensive site assessment to determine optimal unit placement, considering factors such as solar exposure, prevailing winds, and acoustic impact. The outdoor unit should maintain minimum clearance distances of 24 inches on all sides to ensure adequate airflow and maintenance access.

For ground-source installations, conduct thorough geological surveys to determine soil composition and thermal conductivity. Loop field design must account for local climate conditions and building load calculations. Vertical installations typically require 150-200 feet depth per ton of capacity, while horizontal layouts need approximately 1,500-2,000 square feet per ton.

Install the indoor unit in a conditioned space, ensuring proper condensate drainage and easy access for filter changes. Size refrigerant lines according to manufacturer specifications, maintaining proper pitch and insulation. Minimize line length and bends to reduce efficiency losses.

Critical attention must be paid to proper refrigerant charging, as incorrect levels can reduce efficiency by up to 30%. Implement a robust commissioning process, including pressure testing, vacuum procedures, and performance verification. Install advanced controls and monitoring systems to optimize operation based on outdoor temperature and indoor demand.

Always integrate emergency overflow protection and ensure compliance with local building codes. Regular maintenance access points should be clearly marked and easily accessible for service technicians.

Cost-Benefit Analysis

The financial viability of heat pump installations can be assessed through comprehensive ROI analysis, which typically demonstrates favorable returns when integrated with effective building energy management strategies. Initial investment costs for commercial heat pump systems range from $15,000 to $40,000 per unit, depending on capacity and installation requirements. However, operational cost savings typically offset this investment within 3-7 years.

Recent case studies demonstrate annual energy savings of 40-60% compared to traditional HVAC systems, translating to approximately $3,000-$8,000 per year for medium-sized commercial installations. When factoring in available government incentives and utility rebates, which can cover 20-30% of initial costs, the payback period can be reduced to 2-4 years.

Maintenance costs average $200-400 annually, significantly lower than conventional systems requiring $800-1,200 yearly. The extended lifespan of modern heat pumps (15-20 years) further enhances their long-term value proposition. Energy price forecasting models indicate potential ROI improvements of 12-15% over the next decade due to rising traditional energy costs.

For a 50,000-square-foot commercial building, comprehensive analysis shows total lifecycle savings of $120,000-180,000 over 15 years, accounting for installation, maintenance, and operational costs against conventional systems.

Case Study: Commercial Building Retrofit

The Madison Business Center in downtown Seattle serves as a compelling example of successful energy efficient retrofits using heat pump technology. This 12-story commercial building, constructed in 1985, underwent a comprehensive HVAC system upgrade in 2019, replacing its aging gas-fired boilers and conventional air conditioning units with a state-of-the-art variable refrigerant flow (VRF) heat pump system.

The building’s pre-retrofit energy consumption averaged 1.2 million kWh annually, with heating and cooling accounting for approximately 45% of total energy use. The property management team, facing rising operational costs and increasing tenant demands for sustainable solutions, partnered with MEP Engineering Associates to design and implement the heat pump retrofit.

The selected system included multiple Daikin VRV IV heat recovery units, providing simultaneous heating and cooling capabilities across different zones. The installation was completed in phases over six months to minimize disruption to tenant operations. Key components of the retrofit included:

– Installation of 24 outdoor heat pump units on the roof

– Implementation of 180 indoor fan coil units across office spaces

– Integration of a building automation system for optimal temperature control

– Addition of energy recovery ventilators to improve indoor air quality

Post-implementation data has shown remarkable results. The building’s annual energy consumption decreased by 42%, resulting in approximately $145,000 in annual energy cost savings. The new system’s coefficient of performance (COP) averages 3.8, significantly higher than the previous system’s 2.1 COP.

Additional benefits included improved tenant comfort due to more precise temperature control and reduced maintenance requirements. The building’s carbon emissions decreased by an estimated 320 metric tons annually, helping the property achieve LEED Gold certification in 2020.

The project’s total cost of $2.8 million was offset by $420,000 in utility incentives and tax rebates. With the documented energy savings, the retrofit achieved a return on investment period of 5.2 years, meeting the property owner’s financial objectives while demonstrating the viability of heat pump technology in large commercial applications.

Energy-efficient heat pumps represent a pivotal advancement in HVAC technology, offering substantial benefits for both environmental sustainability and operational cost reduction. As demonstrated throughout this analysis, these systems consistently deliver superior performance ratios, with modern units achieving COPs of 3.0 or higher in optimal conditions.

The future outlook for heat pump technology appears increasingly promising, with ongoing innovations in refrigerant technology, smart controls, and system integration capabilities. Manufacturers are developing more efficient compressors and heat exchangers, while emerging variable-speed technology continues to enhance performance across diverse climate conditions.

Industry trends suggest that heat pump adoption will accelerate as building codes evolve and energy efficiency requirements become more stringent. The integration of IoT capabilities and predictive maintenance features will further optimize system performance and reliability. Additionally, the growing focus on electrification in construction presents significant opportunities for heat pump implementation in both new construction and retrofit projects.

For construction professionals and building owners, investing in energy-efficient heat pump systems represents a strategic decision that aligns with both sustainability goals and long-term cost management objectives. As technology continues to advance, these systems will play an increasingly central role in modern HVAC solutions.