Solar construction management stands at the forefront of modern building innovation, revolutionizing how we develop, implement, and oversee construction projects in an increasingly sustainability-focused industry. As renewable energy integration becomes critical to project success, construction managers must master the intricate balance between traditional building practices and solar technology implementation.

The convergence of construction expertise and solar technology demands a sophisticated approach to project planning, resource allocation, and risk management. From initial site assessment and solar array design to final system commissioning, successful solar construction management requires detailed understanding of both construction fundamentals and photovoltaic systems integration. Industry leaders leveraging this expertise are achieving remarkable results: reduced project timelines, optimized energy production, and significantly improved return on investment for stakeholders.

This comprehensive transformation of construction methodology not only addresses current sustainability requirements but positions projects for future energy regulations and market demands. As construction professionals adapt to these evolving requirements, mastering solar construction management becomes not just an advantage, but a necessity for maintaining competitive edge in today’s building industry.

The Strategic Framework of Solar Construction Management

Pre-Construction Planning and Site Assessment

Effective pre-construction planning and site assessment form the foundation of successful solar installations. The process begins with a comprehensive site evaluation that considers multiple factors critical to system performance and construction feasibility.

The initial assessment focuses on solar resource potential, analyzing factors such as site orientation, latitude, and local weather patterns. Professional surveyors utilize advanced solar mapping tools to determine optimal panel placement and predict energy generation capabilities. This data helps establish baseline expectations for system performance and guides equipment selection.

Physical site characteristics require careful examination, including roof structural integrity for rooftop installations or soil composition for ground-mounted systems. Engineers must evaluate existing electrical infrastructure, identifying potential upgrade requirements and determining optimal points of interconnection with the power grid.

Environmental factors also play a crucial role. The assessment must account for current and future shading from nearby structures or vegetation, local wildlife considerations, and potential environmental impact. Compliance with local zoning laws, building codes, and utility requirements needs verification during this phase.

A thorough site logistics plan addresses construction access, material staging areas, and equipment requirements. This planning phase also includes developing preliminary timelines, identifying potential challenges, and establishing mitigation strategies.

For optimal outcomes, stakeholders should engage early in the planning process, including utility representatives, local authorities, and key project team members. This collaborative approach helps identify potential obstacles and ensures alignment with project objectives before construction begins.

Regulatory Compliance and Permitting

Solar construction projects must navigate a complex regulatory landscape that varies by jurisdiction and scope. Compliance begins with obtaining necessary building permits, electrical permits, and environmental assessments. Local authorities typically require detailed site plans, structural analyses, and electrical diagrams before issuing approvals.

Key regulatory considerations include adherence to the National Electrical Code (NEC), specifically Article 690 which governs solar photovoltaic systems. Projects must also comply with International Building Code (IBC) requirements for structural integrity and wind resistance. Many jurisdictions are now aligning their requirements with zero energy building standards, necessitating additional documentation and compliance measures.

Fire safety regulations demand specific setbacks, access pathways, and marking requirements for roof-mounted systems. Environmental impact assessments may be required, particularly for ground-mounted installations or projects in environmentally sensitive areas. Historical district installations often face additional scrutiny and aesthetic requirements.

Professional certification requirements vary by region, with many jurisdictions mandating NABCEP certification for installers. Insurance requirements typically include general liability coverage and worker’s compensation. Interconnection agreements with utility companies must be secured before system activation, ensuring compliance with grid connection standards and safety protocols.

Successful project execution requires early engagement with authorities having jurisdiction (AHJ) and careful documentation throughout the permitting process. Many jurisdictions now offer expedited permitting for standard residential installations, though commercial projects typically require more extensive review.

Integration with Construction Project Management

Timeline Coordination and Resource Allocation

Effective timeline coordination and resource allocation are critical components in successful solar construction projects, requiring meticulous planning and synchronization with traditional energy efficient construction practices. Project managers must develop comprehensive schedules that account for both conventional construction activities and solar installation requirements, ensuring optimal workflow integration.

The process typically begins with a detailed resource assessment, including workforce availability, equipment needs, and material logistics. Solar installations require specialized crews working alongside traditional construction teams, necessitating careful coordination to prevent workflow conflicts. Project managers should implement buffer periods between critical activities to accommodate potential weather delays or technical challenges specific to solar installations.

Key considerations in resource allocation include:

– Scheduling specialized solar installers during appropriate construction phases

– Coordinating equipment delivery and storage to minimize site congestion

– Managing crane and lifting equipment availability for panel installation

– Ensuring adequate safety personnel and equipment throughout the project

– Maintaining material flow to prevent installation delays

Advanced project management software and digital tools help optimize resource utilization by tracking real-time progress and adjusting schedules dynamically. These systems can identify potential conflicts before they occur and suggest alternative scheduling solutions to maintain project momentum.

Weather considerations play a crucial role in timeline planning, as solar installation activities are particularly sensitive to environmental conditions. Project managers should build weather contingencies into the schedule and maintain flexibility in resource allocation to redirect teams to indoor tasks during adverse conditions.

Material procurement and storage require strategic planning to ensure panels, mounting systems, and electrical components arrive on-site at optimal times. Just-in-time delivery strategies can help minimize storage requirements while ensuring materials are available when needed. This approach requires close coordination with suppliers and careful monitoring of lead times for specialized solar equipment.

Success in timeline coordination often depends on establishing clear communication channels between all stakeholders, including general contractors, solar installation teams, electrical subcontractors, and inspection authorities. Regular coordination meetings and progress updates help maintain alignment and allow for quick resolution of potential conflicts.

Quality Control and Safety Protocols

Quality control and safety protocols are fundamental components of successful solar construction projects, requiring rigorous adherence to industry standards and best practices. The implementation of comprehensive quality management systems begins with thorough documentation and regular inspections throughout the installation process.

Key safety protocols must address both electrical and structural aspects of solar installations. Workers should be certified in solar PV installation and follow OSHA guidelines for fall protection and electrical safety. Personal protective equipment (PPE), including hard hats, safety harnesses, and insulated gloves, is mandatory for all personnel on site.

Quality control measures should include:

– Pre-installation equipment inspection and testing

– Verification of mounting system structural integrity

– Regular calibration of installation tools and testing equipment

– Documentation of all electrical connections and grounding systems

– Third-party inspection of critical system components

– Performance testing before system activation

Construction managers must implement a systematic approach to quality assurance, incorporating multiple checkpoints during the installation process. This includes detailed checklists for each phase of construction, from foundation work to final commissioning.

Weather monitoring and environmental conditions assessment are crucial aspects of safety protocols. Installation work should cease during adverse weather conditions, including high winds, rain, or extreme temperatures that could compromise worker safety or installation quality.

Documentation plays a vital role in quality control. Maintaining detailed records of:

– Equipment specifications and serial numbers

– Installation procedures and modifications

– Test results and commissioning data

– Safety incident reports and corrective actions

– Warranty information and maintenance schedules

Regular team meetings and toolbox talks should address safety concerns and quality control updates. These sessions ensure all team members understand current protocols and any recent modifications to installation procedures.

Post-installation quality control should include comprehensive system testing, including:

– Voltage and current measurements

– Insulation resistance testing

– Performance ratio verification

– Visual inspection of all components

– Thermal imaging to identify potential issues

These protocols not only ensure safety and quality but also contribute to long-term system reliability and performance optimization.

Technology and Tools in Solar Construction

Digital Planning and Monitoring Systems

Modern solar construction projects rely heavily on sophisticated digital tools and systems that streamline planning, implementation, and monitoring processes. These platforms integrate with existing smart building technologies to provide comprehensive project oversight and optimization capabilities.

Industry-standard software solutions like BIM (Building Information Modeling) enable precise solar array placement and orientation analysis, factoring in site-specific conditions such as shade patterns, structural loads, and local weather data. These tools generate detailed 3D models that help teams identify potential installation challenges before breaking ground.

Performance monitoring systems utilize real-time data collection through IoT sensors to track energy production, system efficiency, and maintenance requirements. Advanced analytics platforms process this information to generate actionable insights, enabling proactive maintenance scheduling and system optimization. Many solutions now incorporate machine learning algorithms to predict potential issues and optimize energy production based on historical performance data.

Project management platforms specifically designed for solar construction integrate scheduling, resource allocation, and quality control functions. These systems typically feature mobile accessibility, allowing field teams to access crucial information and update project status in real-time. Documentation management capabilities ensure compliance with regulatory requirements while maintaining detailed records of installations, inspections, and maintenance activities.

Regular system updates and cloud-based storage solutions ensure data security while facilitating seamless collaboration among project stakeholders, from designers to installers and maintenance teams.

Equipment and Installation Technologies

Modern solar construction relies on sophisticated equipment and cutting-edge installation technologies to ensure optimal system performance and efficiency. Advanced mounting systems, including ballasted racking for flat roofs and penetrating mounts for pitched surfaces, form the foundation of reliable installations. These systems are complemented by microinverter technology, which enables panel-level power conversion and enhanced monitoring capabilities.

Precision tools like solar pathfinders and irradiance meters help installers determine optimal panel placement, while drone technology with thermal imaging capabilities assists in site surveys and post-installation inspections. Digital design software, incorporating 3D modeling and shade analysis, enables precise system layout and performance predictions before physical installation begins.

Installation crews now utilize automated panel cleaning systems and robotic installation assistants to improve efficiency and reduce labor costs. Smart junction boxes and rapid shutdown devices enhance system safety and compliance with current electrical codes. Wire management solutions have evolved to include integrated cable trays and weatherproof conduit systems that protect crucial electrical components while maintaining aesthetic appeal.

Quality control equipment, such as I-V curve tracers and infrared cameras, allows teams to verify proper installation and system functionality. Remote monitoring platforms provide real-time performance data and predictive maintenance alerts, ensuring optimal system operation throughout its lifecycle. These technological advancements continue to streamline installation processes while improving overall system reliability and performance.

Cost Management and ROI Optimization

Budget Planning and Cost Control

Effective budget planning and cost control are critical components of successful solar construction projects. Initial cost estimation must account for equipment procurement, installation labor, permitting fees, and potential contingencies. Industry best practices recommend allocating 10-15% of the total budget as a contingency reserve to address unforeseen challenges.

Cost tracking tools and software platforms specifically designed for solar projects help maintain real-time visibility of expenditures against budgeted amounts. Regular financial monitoring enables project managers to identify cost overruns early and implement corrective measures promptly. Key performance indicators (KPIs) such as cost variance, schedule performance index, and earned value metrics should be monitored throughout the project lifecycle.

Material cost management requires strategic procurement planning and careful vendor selection. Establishing relationships with reliable suppliers and negotiating bulk purchase agreements can significantly reduce equipment costs. Additionally, implementing just-in-time delivery schedules helps minimize storage costs and reduce the risk of material damage.

Labor costs often represent a substantial portion of the budget. Efficient crew scheduling, proper training, and productivity monitoring are essential for controlling these expenses. Implementation of lean construction principles can help optimize workflow and reduce waste, ultimately leading to cost savings.

Change order management is crucial for maintaining budget integrity. A formal change control process should be established to evaluate the financial impact of modifications and secure appropriate approvals before implementation. Documentation of all cost-related decisions and changes provides accountability and supports future project planning efforts.

Long-term Value and Energy Savings

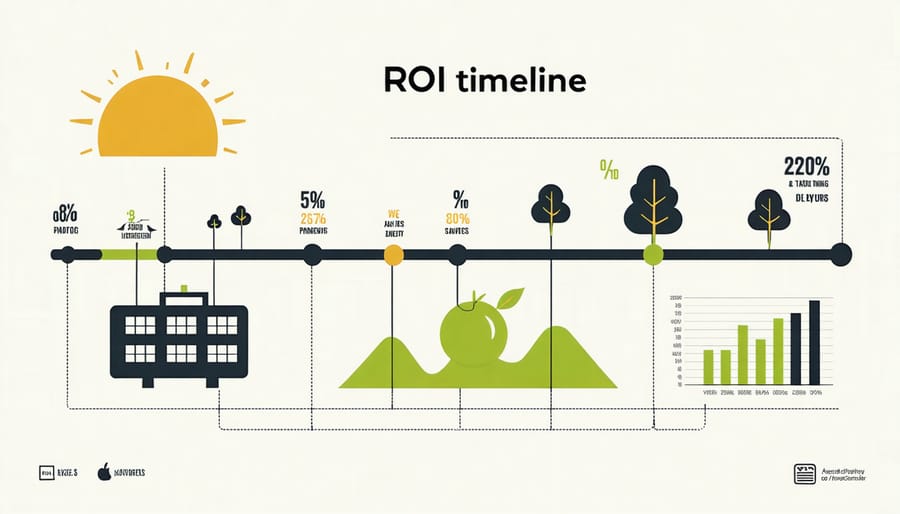

The integration of solar technology in construction projects represents a significant investment with compelling long-term returns. Analysis of recent industry data shows that commercial solar installations typically achieve payback periods of 4-7 years, with system lifespans extending beyond 25 years. These cost-saving energy systems continue to generate value long after the initial investment is recovered.

Construction managers should consider several key financial benefits when evaluating solar implementations. First, operational cost reduction through decreased utility expenses typically ranges from 40-75% annually. Second, federal and state incentives, including tax credits and accelerated depreciation, can offset 40-60% of initial installation costs. Third, renewable energy certificates (RECs) provide additional revenue streams throughout the system’s lifecycle.

Case studies from recent commercial projects demonstrate that buildings with integrated solar solutions command premium lease rates and higher property values, typically 7-10% above market average. Furthermore, the implementation of smart monitoring systems enables precise tracking of energy production and consumption, allowing for optimization of building operations and additional cost savings.

When factoring in rising utility costs, which historically increase 2-3% annually, the long-term value proposition becomes even more compelling. Modern solar installations also contribute to building resilience and energy independence, providing critical advantages during grid disruptions while maintaining operational continuity.

The evolving landscape of solar construction management presents both opportunities and challenges for industry professionals. As we’ve explored throughout this article, successful implementation requires a careful balance of technical expertise, strategic planning, and innovative project management approaches. The integration of solar technologies into construction projects has become increasingly sophisticated, driven by advances in photovoltaic technology, improved installation methods, and enhanced monitoring systems.

Looking ahead, the solar construction sector is poised for significant growth, with projections indicating a continued expansion of solar installations across commercial, residential, and utility-scale projects. The emergence of smart building technologies, coupled with more efficient energy storage solutions, will further transform how we approach solar construction management. Industry professionals must stay adaptable and embrace continuous learning to remain competitive in this dynamic field.

Key success factors will continue to revolve around comprehensive pre-construction planning, effective stakeholder communication, and robust quality control measures. The importance of sustainable practices and regulatory compliance will only increase as environmental standards become more stringent. Construction managers must also prepare for the integration of artificial intelligence and automation in project monitoring and maintenance protocols.

The future outlook for solar construction management is decidedly positive, with increasing client demand and favorable policy environments supporting industry growth. However, success will depend on construction professionals’ ability to adapt to new technologies, maintain high safety standards, and deliver projects that meet both economic and environmental objectives. As the industry matures, we can expect to see more standardized practices, improved efficiency metrics, and innovative solutions that will further streamline solar construction management processes.