Discover how an energy recovery ventilator (ERV) can revolutionize your building’s efficiency and indoor air quality. This innovative technology harnesses the power of heat exchange to minimize energy waste while ensuring a steady supply of fresh, filtered air. By recapturing energy from exhaust air and preconditioning incoming air, ERVs can significantly reduce your HVAC system’s workload, leading to substantial energy savings and a more comfortable, healthier indoor environment.

What is an Energy Recovery Ventilator (ERV)?

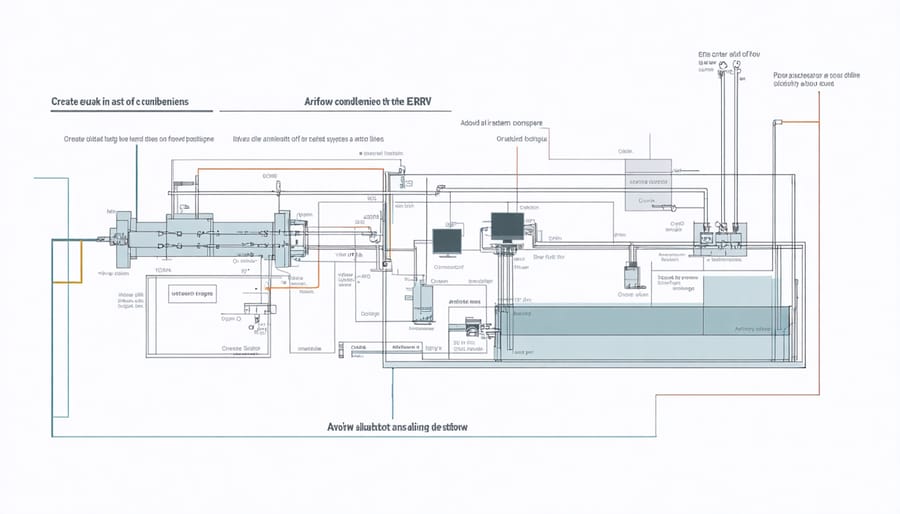

Components of an ERV System

An ERV system typically consists of two fans, two heat exchange cores, filters, and a control system. The fans, usually located in the supply and exhaust air streams, drive the airflow through the system. The heat exchange cores, made of heat-conducting materials like aluminum or polymer, facilitate the transfer of heat and moisture between the outgoing and incoming air streams without mixing the air. Filters positioned before the cores remove dust, pollutants, and other particles from both air streams, ensuring clean air enters the building and protecting the ERV components. The control system manages the operation of the fans, monitors airflow, and may include sensors for temperature, humidity, and air quality to optimize the system’s performance based on indoor and outdoor conditions. These components work together to provide efficient, controlled ventilation while minimizing energy loss.

ERV Operating Principle

The core operating principle of an energy recovery ventilator (ERV) is the transfer of heat and moisture between two air streams: the incoming fresh air and the outgoing exhaust air. This process is facilitated by a heat exchanger core, typically made of polymer or aluminum, which allows for the exchange of both sensible (temperature) and latent (moisture) energy. As the two air streams pass through the core, heat and moisture are transferred from the warmer, more humid stream to the cooler, drier stream. This process preconditions the incoming fresh air, reducing the load on the HVAC system and improving indoor air quality. The efficiency of this energy transfer depends on factors such as the core material, airflow rate, and temperature and humidity differences between the two air streams. By recovering energy that would otherwise be lost through ventilation, ERVs help to maintain a comfortable indoor environment while minimizing energy consumption.

Benefits of Installing an ERV

Improved Indoor Air Quality

An energy recovery ventilator (ERV) plays a crucial role in maintaining healthy indoor air quality by continuously replacing stale, polluted air with fresh, filtered outdoor air. By utilizing advanced filtration systems, ERVs effectively remove airborne contaminants such as dust, pollen, volatile organic compounds (VOCs), and other harmful particles. Moreover, ERVs help regulate indoor humidity levels, preventing the growth of mold, mildew, and other moisture-related issues that can negatively impact occupant health and building integrity. By maintaining optimal humidity and ensuring a constant supply of clean, fresh air, ERVs create a healthier, more comfortable indoor environment for occupants while minimizing the risk of respiratory problems and other health concerns associated with poor air quality.

Energy Efficiency and Cost Savings

Energy recovery ventilators significantly reduce energy consumption by recovering heat from exhaust air and transferring it to incoming fresh air. This process minimizes the load on HVAC systems, leading to substantial energy savings. By preconditioning the incoming air, ERVs reduce the energy required for heating and cooling, resulting in lower utility costs. Studies have shown that ERVs can recover up to 80% of the energy from exhaust air, making them a cost-effective solution for building energy management. The energy savings achieved by ERVs can lead to a quick return on investment, making them an attractive option for energy-conscious construction projects.

Enhanced Comfort and Ventilation

Energy recovery ventilators (ERVs) enhance indoor comfort by providing a steady supply of fresh, filtered air without causing drafts or temperature fluctuations. By transferring heat and moisture between the incoming and outgoing air streams, ERVs maintain a balanced, comfortable indoor environment. The continuous ventilation removes stale air, odors, and pollutants while minimizing the impact on heating and cooling systems. This results in improved air quality and a more pleasant indoor atmosphere for occupants. ERVs are designed to operate quietly and efficiently, ensuring a comfortable living or working space without noticeable noise or air movement.

Reduced Environmental Impact

Energy recovery ventilators contribute to reduced environmental impact by lowering energy consumption in buildings. By recovering energy from exhaust air to precondition incoming fresh air, ERVs minimize the load on heating and cooling systems. This energy efficiency translates to decreased fossil fuel consumption and lower greenhouse gas emissions. In commercial buildings, where HVAC systems account for a significant portion of energy use, ERVs can substantially reduce the carbon footprint. As businesses and organizations prioritize sustainability, implementing ERVs becomes an attractive solution for meeting green building standards and reducing environmental impact while maintaining optimal indoor air quality.

Applications and Installation Considerations

Residential and Commercial Applications

Energy recovery ventilators are essential components in both residential and commercial buildings, ensuring optimal indoor air quality and energy efficiency. In homes, ERVs help maintain a comfortable and healthy living environment by continuously exchanging stale indoor air with fresh outdoor air while minimizing energy loss. This is particularly crucial in modern, tightly-sealed homes that prioritize energy conservation. In commercial settings such as offices, schools, and other public buildings, ERVs play a vital role in meeting ventilation requirements and maintaining a productive and healthy indoor environment. By incorporating ERVs into smart city infrastructure, architects and engineers can design buildings that are not only energy-efficient but also promote the well-being of occupants. Moreover, the installation of ERVs is not limited to new construction; they can also be incorporated into existing buildings as part of retrofit projects, making them a valuable addition to DIY construction projects for homeowners and professionals alike.

Sizing and Placement Guidelines

When selecting an ERV for your project, consider factors such as the building’s size, occupancy, and ventilation requirements. ASHRAE Standard 62.1 provides guidelines for determining ventilation rates based on space type and occupancy. Generally, aim for an ERV that can handle at least 70-80% of the building’s total ventilation needs.

Proper placement is crucial for optimal ERV performance. Install the unit in a central location, such as a mechanical room or utility closet, to minimize ductwork and maintain easy access for maintenance. Ensure the ERV is located away from potential contaminant sources, such as exhaust vents or parking garages.

Consider the climate and building orientation when deciding on ERV placement. In colder regions, position the unit to minimize the risk of freezing condensate. For buildings with significant solar heat gain, locate the ERV to take advantage of natural ventilation and cooling opportunities.

Consult with experienced HVAC professionals to determine the best sizing and placement for your specific project requirements.

Integration with Existing HVAC Systems

Energy recovery ventilators can be seamlessly integrated with various HVAC systems, including forced air, radiant heating, and ductless mini-splits. In forced air systems, ERVs are typically installed in the ductwork, allowing for efficient heat and moisture transfer between incoming fresh air and outgoing exhaust air. For radiant heating systems, ERVs can be installed independently, ensuring proper ventilation without interfering with the heating process. When paired with ductless mini-splits, ERVs provide a compact, efficient solution for both ventilation and temperature control. By working in conjunction with existing HVAC setups, ERVs help maintain indoor air quality, reduce energy consumption, and optimize overall system performance.

Real-World Case Studies

Case Study 1: Sustainable Office Building, Seattle, WA

In 2018, a 12-story office building in Seattle implemented an ERV system as part of its sustainable design. The ERV system, combined with other energy-efficient technologies, resulted in a 40% reduction in energy consumption compared to a conventional building. The ERV system allowed for improved indoor air quality and thermal comfort while minimizing energy waste. This project showcased the effectiveness of ERVs in large-scale commercial applications.

Case Study 2: High-Performance School, Boston, MA

A newly constructed high school in Boston incorporated an ERV system to ensure a healthy learning environment and reduce energy costs. The ERV system provided fresh air to classrooms and common areas while recovering energy from the exhaust air. The school reported a 35% decrease in heating and cooling costs, as well as improved student and teacher satisfaction with indoor air quality. This case study demonstrates the benefits of ERVs in educational facilities, where indoor air quality is crucial for occupant health and well-being.

Conclusion

Energy recovery ventilators are essential components in creating energy-efficient and healthy buildings. As demonstrated throughout this article, ERVs offer numerous benefits, including improved indoor air quality, reduced energy consumption, and lower operating costs. By transferring heat and moisture between incoming and outgoing air streams, ERVs minimize the energy required to condition fresh air, resulting in significant energy savings. Moreover, ERVs help maintain a comfortable indoor environment by regulating humidity levels and removing pollutants, contributing to the well-being of building occupants. With their versatility and adaptability, ERVs can be applied in various settings, from residential homes to commercial and industrial facilities. When considering the installation of an ERV system, it is crucial to work with experienced professionals who can assess the specific needs of the building and design an optimized solution. By incorporating energy recovery ventilators into building projects, construction professionals and decision-makers can create structures that are not only energy-efficient but also promote the health and comfort of their occupants, ultimately contributing to a more sustainable built environment.