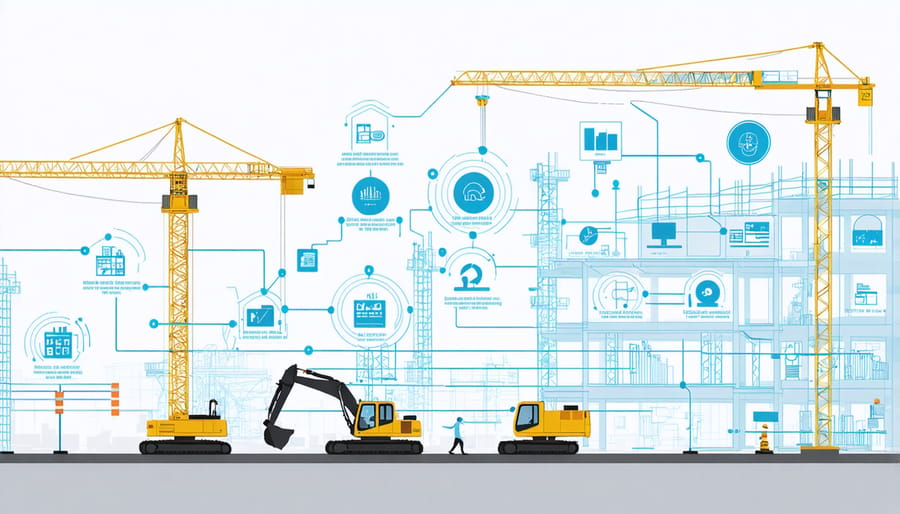

The Internet of Things (IoT) is revolutionizing construction project delivery, driving a 25% increase in productivity and reducing project costs by up to 30% across major construction sites worldwide. From real-time equipment tracking to predictive maintenance systems, IoT sensors and connected devices are transforming traditional construction workflows into data-driven operations. Industry leaders leveraging IoT technologies report significant improvements in site safety, resource optimization, and project timeline adherence.

Smart construction sites now utilize interconnected systems of sensors, wearables, and automated machinery to capture over 50,000 data points daily, enabling precise decision-making and proactive risk management. These technologies have become particularly crucial as the construction industry faces mounting pressure to improve efficiency while maintaining strict safety standards and sustainability goals. With the global construction IoT market projected to reach $16.8 billion by 2024, organizations that embrace these digital innovations position themselves at the forefront of industry advancement.

This transformation extends beyond mere technology adoption – it represents a fundamental shift in how construction projects are planned, executed, and managed. By integrating IoT solutions into core operations, construction companies are creating smarter, safer, and more sustainable building environments while establishing new benchmarks for project efficiency and quality control.

Real-Time Site Monitoring Transforms Decision Making

Equipment Performance Tracking

IoT sensors and telematics systems are revolutionizing how construction companies monitor and manage their equipment fleet. Through real-time data collection and advanced equipment maintenance analytics, contractors can now track crucial performance metrics including fuel consumption, engine hours, idle time, and operational efficiency.

These smart monitoring systems provide instant alerts for potential mechanical issues, helping prevent costly breakdowns and optimize maintenance schedules. Data from IoT devices enables project managers to analyze equipment utilization patterns, ensuring optimal deployment of machinery across multiple job sites.

Case studies have shown that construction companies implementing IoT-based equipment monitoring systems typically achieve 15-20% reduction in maintenance costs and up to 30% improvement in equipment utilization rates. The technology also enhances safety by monitoring operator behavior and equipment stress levels, while providing valuable insights for equipment lifecycle management and replacement planning.

By integrating equipment performance data with project management systems, construction firms can make data-driven decisions about equipment allocation, maintenance timing, and fleet expansion strategies, ultimately improving project efficiency and profitability.

Environmental Monitoring Systems

Environmental monitoring systems powered by IoT technology have revolutionized how construction sites manage and respond to environmental conditions. Advanced sensors continuously track critical parameters including temperature, humidity, dust levels, noise pollution, and air quality in real-time, enabling proactive site management and enhanced worker safety.

These sophisticated monitoring systems utilize interconnected sensors strategically placed throughout construction sites to create a comprehensive environmental data network. Temperature and humidity sensors help maintain optimal conditions for material storage and curing processes, particularly crucial for concrete work and specialized installations. Dust monitoring devices ensure compliance with air quality regulations and worker safety standards, while also helping to minimize the environmental impact on surrounding areas.

Real-time alerts notify site managers when environmental parameters exceed predetermined thresholds, allowing for immediate corrective action. This data-driven approach not only improves workplace safety but also optimizes construction schedules by identifying ideal conditions for specific tasks. Integration with building management systems enables long-term environmental performance tracking, contributing to sustainable construction practices and reduced energy consumption throughout the project lifecycle.

Safety and Risk Management Evolution

Worker Safety Monitoring

IoT wearable devices have revolutionized worker safety monitoring in construction sites, providing real-time data and proactive safety measures. These smart devices, including hard hats, vests, and wristbands, continuously monitor vital signs, location, and environmental conditions to prevent accidents and respond quickly to emergencies.

Advanced sensors in wearable devices track workers’ physical conditions, including heart rate, body temperature, and fatigue levels. They can detect falls, impacts, or sudden movements that might indicate an accident. Environmental sensors monitor hazardous conditions like toxic gas levels, extreme temperatures, and excessive noise, alerting workers before they enter dangerous areas.

GPS and RFID technology enable precise worker tracking, ensuring personnel don’t enter restricted zones and allowing quick location of workers during emergencies. Geofencing capabilities automatically trigger alerts when workers breach designated safety boundaries or approach heavy machinery without proper authorization.

These devices integrate with central monitoring systems, enabling supervisors to maintain comprehensive oversight of site safety. Real-time alerts and automated emergency protocols significantly reduce response times during incidents. Data collected from these devices also helps identify patterns in safety incidents, enabling preventive measures and improved safety training programs.

Recent case studies show that construction sites implementing IoT safety monitoring systems report up to 50% reduction in workplace accidents and improved emergency response times by 65%.

Structural Health Monitoring

Real-time structural health monitoring through IoT sensors represents a significant advancement in construction safety and building integrity assessment. These sophisticated sensor networks continuously monitor critical parameters such as strain, vibration, displacement, and load distribution throughout the construction process.

Strategic placement of accelerometers, strain gauges, and displacement sensors enables project teams to detect potential structural issues before they become critical. These devices transmit data to centralized monitoring systems, providing immediate alerts when measurements exceed predetermined thresholds. For instance, vibration sensors can detect unusual movement patterns that might indicate foundation settling or structural stress, while strain gauges monitor the deformation of key structural elements.

Modern IoT monitoring systems also incorporate environmental sensors to track temperature fluctuations, humidity levels, and concrete curing conditions, all of which can significantly impact structural integrity. This comprehensive monitoring approach allows construction teams to make data-driven decisions about construction sequencing and loading patterns.

The integration of structural health monitoring has proven particularly valuable in high-rise construction and complex infrastructure projects, where real-time data helps ensure compliance with safety standards and optimal building performance. Additionally, this technology creates a detailed historical record of structural behavior, valuable for both immediate construction management and long-term building maintenance planning.

Resource Optimization Through Data Analytics

Energy Consumption Management

IoT technology has revolutionized energy consumption management in construction projects through intelligent monitoring and automation systems. Smart sensors deployed across construction sites continuously collect real-time data on power usage, enabling project managers to implement effective sustainable resource management strategies.

Advanced IoT systems can automatically adjust power distribution based on actual usage patterns, reducing waste during non-peak hours. For example, lighting and HVAC systems can be programmed to operate only when specific zones are actively being used, resulting in energy savings of up to 30% compared to traditional systems.

Smart meters and energy monitoring devices provide detailed analytics on equipment power consumption, helping identify energy-intensive processes and potential optimization opportunities. This data-driven approach enables construction firms to establish baseline energy requirements and implement targeted reduction strategies.

Recent case studies show that construction sites utilizing IoT-based energy management systems have achieved significant cost savings while maintaining operational efficiency. These systems also support compliance with environmental regulations by providing accurate carbon footprint data and facilitating more environmentally conscious construction practices.

Material Usage Tracking

IoT sensors and tracking systems have revolutionized material usage monitoring in construction projects, enabling real-time inventory management and significant waste reduction. Smart sensors attached to materials and equipment continuously transmit data about consumption patterns, storage conditions, and movement across construction sites.

Construction firms implementing IoT-based material tracking systems report up to 30% reduction in material waste and a 25% improvement in inventory accuracy. These systems automatically monitor stock levels, trigger reorder notifications, and provide precise location data for materials across large construction sites.

Advanced IoT platforms integrate with procurement systems to optimize ordering processes, preventing both stockouts and excess inventory. Environmental sensors monitor storage conditions for sensitive materials, ensuring proper temperature, humidity, and handling requirements are maintained.

Real-world applications include RFID-tagged prefabricated components that can be tracked from factory to installation, and concrete sensors that monitor curing conditions and material properties. This level of monitoring enables just-in-time delivery, reduces storage costs, and minimizes material degradation due to improper storage or handling.

The data collected through IoT devices also supports better forecasting and planning for future projects, creating a cycle of continuous improvement in material management efficiency.

Implementation Challenges and Solutions

While IoT technology offers significant advantages in construction, implementing these systems presents several challenges that require strategic solutions. Network connectivity remains a primary concern on construction sites, particularly in remote locations or underground areas. To address this, companies are increasingly adopting hybrid network solutions that combine cellular, Wi-Fi, and mesh networks to ensure consistent data transmission.

Data security poses another significant challenge, as construction IoT systems handle sensitive project information and operational data. Implementation of robust encryption protocols, regular security audits, and multi-factor authentication systems help protect against potential breaches. Additionally, establishing clear data governance policies ensures proper handling of information across all stakeholders.

Cost considerations often present barriers to IoT adoption, especially for smaller contractors. Solutions include phased implementation approaches, starting with high-impact areas like equipment monitoring or safety systems, and gradually expanding as ROI is demonstrated. Some organizations opt for IoT-as-a-service models to reduce initial capital expenditure.

Integration with existing systems and processes presents technical challenges. Success requires careful planning and selection of IoT platforms that offer compatible APIs and support legacy system integration. Training programs for staff members are essential to ensure proper usage and maintenance of IoT systems.

Hardware durability in harsh construction environments remains a concern. Companies are addressing this by selecting ruggedized sensors and devices specifically designed for construction conditions, implementing protective housing solutions, and establishing regular maintenance protocols.

Data standardization across different devices and platforms can be problematic. The solution lies in adopting industry-standard protocols and working with vendors who support open architecture systems, enabling seamless communication between various IoT components.

IoT technology has fundamentally transformed the construction industry by enabling data-driven decision-making and operational efficiency. Through real-time monitoring, predictive maintenance, and automated workflows, IoT solutions have demonstrated their ability to reduce costs by up to 20% while significantly improving project timelines and safety standards. The integration of IoT sensors, cloud computing, and advanced analytics continues to evolve, promising even greater benefits in the years ahead. Industry experts project that by 2025, over 75% of construction companies will incorporate IoT solutions into their core operations. As technology advances and becomes more accessible, we can expect to see enhanced artificial intelligence integration, more sophisticated automation systems, and improved interoperability between different IoT platforms. The future of construction lies in embracing these digital innovations, making IoT adoption not just beneficial but essential for staying competitive in an increasingly technology-driven industry.