Embrace the power of innovation to revolutionize your construction projects. From emerging technologies like 3D printing and robotics to sustainable building materials and lean construction methodologies, cutting-edge techniques are transforming the industry. Discover how these advancements can optimize efficiency, reduce costs, enhance safety, and push the boundaries of what’s possible. Stay ahead of the curve and unlock new opportunities by implementing these game-changing innovations on your next project. Get ready to build smarter, faster, and greener than ever before.

3D Printing

Case Study: 3D Printed Housing Development

In a groundbreaking development, construction company BuildTech has successfully completed a 50-unit housing project using cutting-edge 3D printing technology. The project, located in the heart of a growing urban center, showcases the potential of 3D printing to revolutionize the construction industry.

By leveraging large-scale 3D printers, BuildTech was able to create the structural components of the houses in a fraction of the time required by traditional construction methods. The 3D-printed walls, floors, and roofs were produced off-site in a controlled environment, ensuring precision and quality control. Once printed, these components were transported to the construction site and assembled by skilled workers.

According to BuildTech’s lead engineer, Sarah Johnson, “3D printing allowed us to streamline the construction process, reducing labor costs and minimizing material waste. We were able to create complex shapes and designs that would have been challenging with conventional techniques.” The case study demonstrates the ability of 3D printing to deliver high-quality, sustainable housing solutions rapidly and efficiently.

The 3D-printed houses boast impressive energy efficiency, thanks to the precise insulation and airtight construction made possible by the technology. Residents have reported lower utility bills and improved comfort compared to traditionally built homes.

This pioneering project by BuildTech serves as a testament to the transformative potential of 3D printing in the construction industry, paving the way for more sustainable, efficient, and innovative housing solutions in the future.

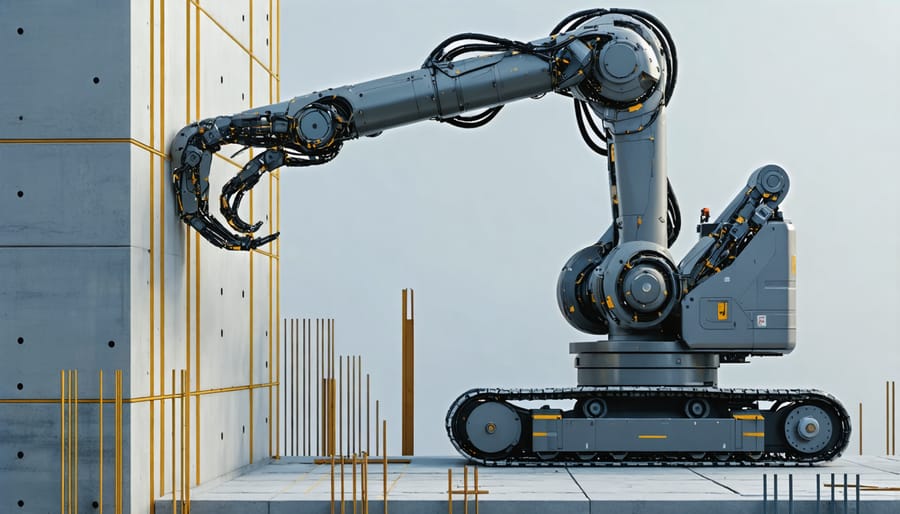

Robotics & Automation

Robotics and automation are revolutionizing the construction industry, offering unprecedented levels of precision, speed, and safety on job sites. From robotic bricklayers to autonomous heavy equipment, these cutting-edge technologies are transforming the way buildings and infrastructure are constructed.

One notable example is the SAM100 (Semi-Automated Mason) by Construction Robotics, a bricklaying robot capable of laying up to 3,000 bricks per day, significantly outpacing human masons. SAM100 ensures consistent quality and reduces the physical strain on workers, allowing them to focus on more complex tasks.

Autonomous heavy equipment, such as self-driving excavators and dozers, is another game-changer. Companies like Built Robotics are developing AI-powered systems that can operate construction machinery with minimal human intervention. These machines can work around the clock, increasing productivity and reducing project timelines.

Drones are also making their mark in construction, offering aerial surveying, progress monitoring, and safety inspection capabilities. Equipped with high-resolution cameras and advanced sensors, drones can quickly gather data from hard-to-reach areas, enabling more accurate site planning and reducing the risk of accidents.

In addition to on-site robots, prefabrication and modular construction techniques are leveraging automation to streamline the building process. Factories equipped with robotic assembly lines can produce building components with unparalleled precision and efficiency, which are then transported to the construction site for rapid assembly. This approach minimizes waste, reduces construction time, and improves overall build quality.

As these technologies continue to advance, the construction industry must adapt and upskill its workforce to effectively integrate robotics and automation into their projects. By embracing these innovations, construction professionals can unlock new levels of efficiency, safety, and quality, ultimately reshaping the built environment of the future.

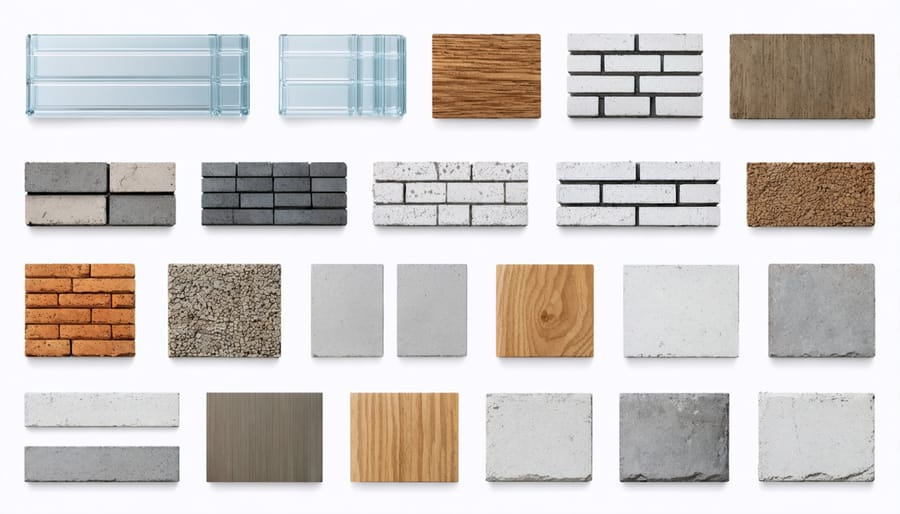

Sustainable Materials

The construction industry is witnessing a surge in innovative, eco-friendly building materials that are revolutionizing the way we approach sustainability in the built environment. Self-healing concrete, for instance, is a game-changer in the realm of sustainable materials. This cutting-edge technology utilizes special bacteria that can repair cracks in concrete, extending the lifespan of structures and reducing the need for costly repairs and replacements. Another groundbreaking material is transparent wood, which is created by removing lignin from wood and replacing it with a transparent polymer. This process results in a material that is stronger than glass, more insulating than traditional wood, and allows natural light to pass through, reducing the need for artificial lighting. Recycled plastic bricks are also gaining traction as a sustainable alternative to conventional building materials. These bricks are made from discarded plastic waste, offering a viable solution to the global plastic pollution crisis while providing a durable and long-lasting construction material. As the demand for sustainable construction grows, these innovative materials are poised to play a crucial role in shaping the future of the industry, offering architects, engineers, and project managers new tools to create buildings that are not only environmentally friendly but also resilient and cost-effective.

Modular & Prefabricated Construction

Modular and prefabricated construction methods are revolutionizing the building industry by streamlining projects and reducing on-site labor requirements. These innovative techniques involve constructing building components off-site in a controlled factory environment, then transporting and assembling them at the construction site. By leveraging advanced manufacturing processes and materials, modular and prefab construction offer numerous benefits over traditional site-built methods.

One of the primary advantages is increased efficiency and speed. Factory-based construction allows for parallel production of building components, minimizing delays due to weather or site constraints. Additionally, the controlled environment enables strict quality control and reduces material waste. As a result, projects can be completed up to 50% faster than with conventional methods.

Prefabrication also significantly reduces on-site labor requirements. By shifting much of the work to the factory, fewer skilled workers are needed at the construction site. This is particularly advantageous in areas with labor shortages or high labor costs. Moreover, the reduced on-site activity minimizes disruption to surrounding communities and enhances site safety.

Modular construction is not limited to small-scale projects. Advances in technology and materials have enabled the creation of large, complex structures using prefabricated components. From multi-story apartment buildings to hospitals and schools, modular construction is proving its versatility and cost-effectiveness across a wide range of applications.

As the construction industry continues to embrace innovation, modular and prefabricated methods are poised to become increasingly prevalent. By combining the benefits of off-site manufacturing with the flexibility of on-site assembly, these techniques offer a compelling solution to the challenges of modern construction projects.

Smart Construction Technology

The construction industry is undergoing a digital transformation, with smart technologies revolutionizing site management and maintenance practices. Internet of Things (IoT) sensors, artificial intelligence (AI), and advanced data analytics are at the forefront of this shift, enabling construction professionals to optimize operations, reduce costs, and enhance safety.

IoT sensors embedded in equipment, materials, and across construction sites collect real-time data on various parameters such as temperature, humidity, vibration, and location. This data is transmitted to centralized platforms where AI algorithms analyze it to provide actionable insights. For example, sensors can monitor the health of critical assets like cranes and excavators, alerting managers to potential issues before they cause downtime or safety hazards. This predictive maintenance approach minimizes unplanned outages and extends equipment lifespan.

AI-powered tools also streamline project management by automating tasks such as scheduling, resource allocation, and progress tracking. Machine learning algorithms can analyze historical data to predict potential delays or cost overruns, allowing teams to proactively mitigate risks. Additionally, computer vision technology can analyze site images and videos to identify safety violations, quality issues, and productivity bottlenecks.

Data analytics platforms integrate information from multiple sources, providing a holistic view of construction projects. Dashboards and visualization tools enable stakeholders to make data-driven decisions, optimize workflows, and identify areas for improvement. For instance, analyzing data on material usage and waste can help teams adopt lean construction practices and reduce environmental impact.

As smart construction technology continues to evolve, it will play an increasingly vital role in shaping the future of the industry. By embracing these innovations, construction firms can gain a competitive edge, deliver projects more efficiently, and contribute to the development of sustainable, resilient infrastructure.

Conclusion

As the construction industry continues to evolve, innovative techniques will play a crucial role in shaping its future. By adopting advanced technologies, sustainable practices, and collaborative approaches, the industry can overcome challenges, improve efficiency, and deliver projects that meet the ever-changing needs of society. The key takeaways from this exploration of innovative construction techniques highlight the importance of embracing change, investing in research and development, and fostering a culture of continuous improvement. As these techniques advance and become more widely adopted, the construction industry can look forward to a future characterized by enhanced productivity, reduced environmental impact, and the creation of resilient, adaptable structures that stand the test of time.