The construction industry is on the brink of a technological revolution, with innovative concepts poised to transform the way we build. From 3D printing and robotics to sustainable materials and smart cities, these groundbreaking ideas are set to reshape the sector, ushering in a new era of efficiency, sustainability, and creativity.

As the world grapples with pressing challenges like urbanization, climate change, and resource scarcity, the construction industry must adapt and innovate to meet the demands of the future. The recent Infrastructure Bill’s allocation for construction technology is a testament to the growing importance of these innovations in driving economic growth and addressing global issues.

In this article, we will explore the most cutting-edge and influential innovations in construction, delving into their potential to revolutionize the industry. From the advent of AI-powered design tools to the rise of prefabrication and modular construction, we will examine how these concepts are already making their mark and shaping the future of the built environment. Join us as we embark on a journey through the exciting world of innovative construction concepts and discover the limitless possibilities they hold for the industry and society as a whole.

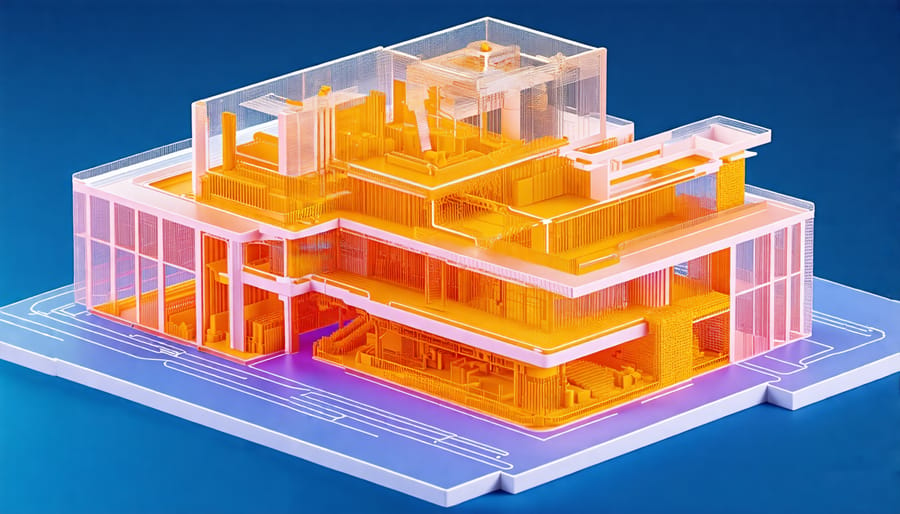

Modular and Prefabricated Construction

Case Study: Modular High-Rise

One remarkable example of modular construction’s potential in high-rise buildings is the award-winning 461 Dean Street project in Brooklyn, New York. Developed by Forest City Ratner Companies, this 32-story residential tower stands as the tallest modular building in the world. The construction process involved the off-site fabrication of 930 modular units, which were then transported to the site and stacked to form the tower’s structure. This innovative approach reduced construction time by approximately 30% compared to traditional methods, while also minimizing on-site waste and noise pollution.

The modular units, manufactured in a controlled factory environment, ensured consistent quality and precision. Each unit arrived at the site with pre-installed electrical wiring, plumbing, and interior finishes, streamlining the assembly process. This method not only expedited the construction timeline but also resulted in a more energy-efficient building, with tighter seals between units and improved insulation.

The success of 461 Dean Street demonstrates the viability of modular construction for high-rise projects, offering a template for future developments. As the industry continues to evolve, we can expect to see more projects like Starbucks’ energy-efficient modular store and large-scale residential towers embracing this innovative construction method. The benefits of reduced construction time, improved quality control, and enhanced sustainability make modular construction an attractive option for developers and architects seeking to push the boundaries of traditional building practices.

3D Printing in Construction

3D printing, also known as additive manufacturing, is revolutionizing the construction industry by offering innovative solutions for rapid prototyping, customization, and full-scale structure creation. This technology allows for the precise layering of materials, such as concrete, plastic, or metal, to create complex shapes and designs that would be difficult or impossible to achieve with traditional construction methods.

One of the most significant advantages of 3D printing in construction is its ability to streamline the prototyping process. Architects and engineers can quickly create scale models of their designs, allowing for more efficient testing and refinement before moving on to full-scale construction. This not only saves time but also reduces material waste and costs associated with traditional prototyping methods.

Moreover, 3D printing enables the creation of highly customized building components, such as intricate facades, unique structural elements, and even entire buildings. By leveraging the flexibility of 3D printing, architects and designers can push the boundaries of creativity and bring their most innovative visions to life.

Real-world applications of 3D printing in construction are already making an impact. For example, in 2019, a Dutch company called MX3D successfully 3D-printed a stainless steel bridge in Amsterdam, showcasing the technology’s potential for creating functional, load-bearing structures. Similarly, companies like ICON and Apis Cor are developing 3D printing systems capable of constructing entire houses in a matter of days, with the goal of addressing housing shortages and providing affordable, sustainable living solutions.

As 3D printing technology continues to advance, it is expected to play an increasingly significant role in shaping the future of construction. By embracing this innovative approach, the industry can look forward to faster, more efficient, and more sustainable building practices that will transform the way we create and experience the built environment.

Smart Materials and Nanotechnology

The construction industry is witnessing a revolution in materials science and nanotechnology, with researchers and companies developing innovative solutions to enhance the performance, durability, and sustainability of buildings and infrastructure. One such breakthrough is the use of self-healing concrete, which contains embedded microcapsules filled with healing agents. When cracks form, these capsules rupture, releasing the agents that seal the cracks and prevent further damage, thereby extending the lifespan of concrete structures and reducing maintenance costs.

Another promising development is the application of carbon nanotubes (CNTs) in construction materials. CNTs are incredibly strong and lightweight, with exceptional mechanical and electrical properties. When incorporated into concrete, steel, or other materials, CNTs can significantly improve their strength, ductility, and resistance to fatigue and corrosion. This advancement opens up new possibilities for designing more resilient and efficient structures, particularly in seismic regions or harsh environments.

Nanotechnology is also being harnessed to create smart coatings and surfaces for buildings. These coatings can exhibit self-cleaning, anti-microbial, or thermal insulation properties, depending on the specific nanoparticles and compounds used. For example, titanium dioxide nanoparticles can be applied to exterior surfaces to break down pollutants and dirt when exposed to sunlight, reducing the need for manual cleaning and improving air quality. Similarly, nanostructured insulation materials, such as aerogels or vacuum insulation panels, offer superior thermal performance while being thinner and lighter than conventional insulation.

In addition to enhancing material properties, nanotechnology is enabling the development of smart sensors and monitoring systems for buildings. By integrating nanoscale sensors into structural components, engineers can continuously monitor the health and performance of buildings in real-time, detecting potential issues before they become critical. This predictive maintenance approach can optimize repair schedules, reduce downtime, and improve overall safety and reliability.

As the construction industry embraces these cutting-edge materials and nanotechnologies, it is crucial for professionals to stay informed about the latest advancements and their potential applications. By leveraging these innovations, the industry can build smarter, stronger, and more sustainable structures that meet the evolving needs of society while minimizing environmental impact and lifecycle costs.

Robotics and Automation

The construction industry is witnessing a significant shift towards robotics and automation, as companies seek to enhance precision, safety, and efficiency on job sites. Robotic systems are being deployed for a wide range of tasks, from bricklaying and welding to painting and demolition. These machines can work tirelessly with unparalleled accuracy, reducing human error and increasing productivity.

One notable example is the use of autonomous vehicles and drones for surveying and site inspection. These technologies enable real-time data collection and analysis, allowing project managers to make informed decisions and identify potential issues early on. Additionally, exoskeletons and wearable robotics are being developed to assist workers in lifting heavy loads and performing repetitive tasks, minimizing the risk of injury and fatigue.

Prefabrication and modular construction are also benefiting from automation. Robotic systems in off-site factories can assemble building components with greater precision and speed, reducing waste and ensuring consistent quality. This approach not only streamlines the construction process but also reduces on-site labor requirements and safety risks.

However, the adoption of robotics and automation in construction faces challenges, such as high upfront costs, the need for specialized training, and the potential for job displacement. As the industry navigates these hurdles, it is crucial for companies to invest in reskilling their workforce and finding ways to integrate human expertise with robotic capabilities.

As robotics and automation continue to advance, they hold immense potential for revolutionizing the construction industry. By embracing these technologies strategically, companies can improve project outcomes, reduce costs, and create safer, more efficient work environments for their employees.

Sustainable and Green Building Innovations

The construction industry is witnessing a paradigm shift towards sustainable and green building practices. Innovative sustainable construction practices are paving the way for a more environmentally conscious future. Energy-efficient designs, such as passive solar architecture and advanced insulation systems, are becoming increasingly popular among architects and engineers. These designs harness natural light and minimize heat loss, reducing the building’s energy consumption and carbon footprint.

Moreover, the use of renewable and recycled materials is gaining traction in the industry. Bamboo, a rapidly renewable resource, is being utilized for flooring, scaffolding, and even structural elements. Recycled steel, concrete, and glass are being incorporated into new construction projects, reducing waste and conserving natural resources.

Green roofs are another innovative concept that is transforming the urban landscape. These living roofs, covered with vegetation, offer numerous benefits, such as improved insulation, reduced stormwater runoff, and enhanced biodiversity. They also help mitigate the urban heat island effect and improve air quality in densely populated areas.

In addition to these innovations, cutting-edge technologies like 3D printing and prefabrication are being leveraged to create more sustainable buildings. 3D printing allows for the precise use of materials, minimizing waste and enabling the creation of complex, energy-efficient designs. Prefabrication, on the other hand, streamlines the construction process, reducing on-site waste and improving quality control.

As the demand for sustainable buildings grows, the construction industry is embracing these innovative practices and technologies. By adopting green building strategies, the sector is not only reducing its environmental impact but also creating healthier, more resilient structures that benefit both occupants and the planet.

Augmented Reality and Virtual Reality

Augmented Reality (AR) and Virtual Reality (VR) technologies are revolutionizing the construction industry by providing immersive design visualization, enhancing training, and fostering collaboration. AR overlays digital information onto the real world, allowing architects, engineers, and construction professionals to visualize designs in real-time, directly on the job site. This technology enables teams to identify potential issues early, make informed decisions, and streamline the construction process.

VR, on the other hand, creates fully immersive digital environments, enabling users to explore and interact with 3D models as if they were physically present. This technology is particularly valuable for design reviews, as it allows stakeholders to experience spaces before they are built, facilitating effective communication and decision-making. VR is also transforming training in the construction industry, providing realistic simulations that help workers develop skills and familiarize themselves with complex tasks in a safe, controlled environment.

Moreover, AR and VR are enhancing collaboration among project teams, regardless of their physical location. By using these technologies, professionals can conduct virtual meetings, share real-time updates, and make decisions collectively, even when working remotely. This collaborative approach leads to improved efficiency, reduced errors, and faster project completion times.

As the construction industry continues to adopt innovative technologies, AR and VR are becoming increasingly integrated with other cutting-edge concepts, such as Digital twins in construction. The combination of these technologies creates a powerful toolkit for professionals to optimize designs, streamline processes, and deliver high-quality projects more efficiently than ever before.

Conclusion

The innovative construction concepts discussed in this article are set to revolutionize the industry, driving efficiency, sustainability, and safety to new heights. From 3D printing and robotics to smart materials and green building techniques, these groundbreaking technologies and methodologies are reshaping how we design, build, and maintain structures. As the construction sector continues to evolve at a rapid pace, it is crucial for professionals to stay informed about the latest advancements and adapt their practices accordingly. By embracing these innovations, the industry can overcome challenges, improve productivity, and deliver projects that meet the evolving needs of society. The future of construction lies in the hands of those who are willing to explore and implement these cutting-edge solutions. As we move forward, it is clear that the most successful companies will be those that prioritize innovation, sustainability, and collaboration, paving the way for a more efficient and resilient built environment.