Transform your construction project outcomes through strategic project procurement management with a systematic, seven-step approach that industry leaders consistently leverage for superior results. In today’s complex construction landscape, where material costs fluctuate and supply chains remain volatile, mastering procurement processes has become a critical differentiator between project success and costly setbacks.

Modern procurement demands precision, compliance, and strategic foresight. From initial needs assessment through contract closure, each step builds upon the previous one to create a robust framework that maximizes value while minimizing risk. Leading construction firms have documented up to 23% cost savings and 35% faster project completion rates when implementing structured procurement methodologies.

This comprehensive guide breaks down the essential procurement steps that drive successful construction projects, incorporating best practices from industry pioneers and real-world case studies. Whether managing large-scale developments or specialized installations, these proven strategies will elevate your procurement processes to new levels of efficiency and effectiveness.

Early Planning and Needs Assessment

Project Scope Definition

A well-defined project scope serves as the foundation for successful procurement in construction projects. This critical first step involves creating detailed specifications that outline project requirements, deliverables, and quality standards. Project managers must collaborate with stakeholders to develop comprehensive documentation that includes technical specifications, performance criteria, and delivery timelines. This documentation should align with established cost management strategies while maintaining flexibility for potential modifications. Key elements include material specifications, quantity requirements, quality benchmarks, and compliance standards. The scope definition should also address risk factors, sustainability requirements, and any specific regulatory compliance needs. Clear articulation of these parameters helps prevent scope creep, reduces procurement disputes, and ensures that all parties have a unified understanding of project objectives. This detailed groundwork significantly impacts project success by minimizing misunderstandings and avoiding costly changes during implementation.

Market Analysis

Market analysis forms the foundation of successful procurement in construction projects. Begin by conducting comprehensive research into current market conditions, including material costs, labor rates, and supply chain dynamics. This research should encompass both local and global markets to identify potential suppliers and understand pricing trends.

Evaluate potential suppliers based on multiple criteria: financial stability, production capacity, quality certifications, and past performance records. Pay particular attention to their track record in similar construction projects and their ability to meet delivery schedules. Request detailed information about their manufacturing processes, quality control measures, and emergency response capabilities.

Develop a supplier assessment matrix that weighs various factors such as price competitiveness, technical capabilities, geographical location, and risk factors. Consider conducting site visits to key suppliers’ facilities to verify their operational capabilities firsthand. This hands-on approach helps in understanding their true capacity and establishing stronger business relationships.

Remember to document all findings systematically and maintain updated market intelligence for future reference. Regular market analysis ensures your procurement strategy remains competitive and aligned with current industry standards.

Strategic Sourcing Development

Supplier Selection Criteria

Establishing robust supplier selection criteria is crucial for successful construction procurement. The evaluation process should incorporate both quantitative and qualitative metrics to ensure comprehensive assessment. Key criteria include financial stability, demonstrated technical capabilities, past performance records, and quality management systems.

Begin by evaluating suppliers’ financial health through credit ratings, revenue trends, and debt ratios. Technical capabilities should be assessed through certifications, equipment ownership, and workforce expertise. Past performance evaluation must consider completion rates, adherence to schedules, and quality of delivered work on similar projects.

Quality management systems should be ISO-certified where applicable, with clear documentation of quality control processes. Safety records and environmental compliance are equally important, including EMR ratings and sustainability practices. Consider geographical proximity for logistics efficiency and local market knowledge.

Weight these criteria according to project-specific requirements using a standardized scoring matrix. This approach enables objective comparison while maintaining transparency in the selection process. Regular performance reviews should be incorporated into the criteria to ensure continuous improvement and accountability throughout the project lifecycle.

Risk Management Integration

Risk management integration within the procurement process is crucial for successful construction project delivery. Begin by conducting a comprehensive risk assessment that identifies potential threats across supply chain, financial, operational, and regulatory dimensions. Document these risks in a structured matrix, categorizing them by likelihood and potential impact on project outcomes.

Develop mitigation strategies for each identified risk, incorporating specific requirements into supplier evaluation criteria and contract terms. Consider implementing performance bonds, warranties, and insurance requirements to protect against supplier default or quality issues. For critical materials or services, establish contingency plans including alternative suppliers and buffer stock requirements.

Regular supplier audits and performance monitoring should be integrated into the procurement strategy, enabling early detection of potential issues. Utilize digital tools and analytics platforms to track supplier performance metrics, market conditions, and emerging risks in real-time. This data-driven approach allows for proactive risk management and informed decision-making.

Ensure your procurement team maintains open communication channels with stakeholders, including suppliers, project managers, and legal advisors. This collaborative approach helps identify and address risks before they impact project timelines or budgets, while maintaining compliance with industry regulations and standards.

Tender Documentation and RFP Process

Document Preparation

Document preparation forms a critical foundation in the procurement process, requiring meticulous attention to detail and comprehensive understanding of project requirements. The tender documents package typically includes technical specifications, drawings, bill of quantities, general conditions, and special conditions of contract. Each component must be carefully crafted to ensure clarity and completeness while eliminating potential ambiguities that could lead to disputes.

Project managers should incorporate detailed scope statements, precise technical requirements, and clear performance criteria into the documentation. Quality standards, delivery timelines, and specific material specifications need explicit definition to prevent misinterpretation. The inclusion of evaluation criteria and submission requirements helps potential bidders understand how their proposals will be assessed.

Risk allocation clauses, payment terms, and contract conditions require careful consideration during document preparation. Environmental requirements, safety standards, and local regulatory compliance should also be clearly outlined. Modern procurement practices often integrate sustainability criteria and innovation requirements into tender documents, reflecting evolving industry standards.

Before finalization, all documents should undergo thorough review by technical experts, legal advisors, and key stakeholders to ensure consistency and compliance with organizational objectives and regulatory requirements.

Bid Management

Effective bid management is crucial for securing optimal value and maintaining transparency throughout the procurement process. Begin by developing a comprehensive Request for Proposal (RFP) that clearly outlines project requirements, specifications, and evaluation criteria. This document should include detailed scope descriptions, technical requirements, and performance expectations to ensure all bidders understand the project parameters.

Establish a structured communication channel for supplier inquiries and maintain detailed records of all interactions. Schedule a pre-bid meeting to address questions and provide additional clarification, ensuring all potential suppliers receive identical information. This approach promotes fair competition and reduces the risk of misunderstandings.

During the bid evaluation phase, implement a systematic scoring system based on predetermined criteria such as price, technical capability, past performance, and quality assurance measures. Consider using a weighted scoring matrix to objectively assess each proposal. Document all evaluation decisions and maintain clear audit trails.

Keep bidders informed of timelines and process updates through formal communications. Once the evaluation is complete, provide constructive feedback to unsuccessful bidders while maintaining professional relationships for future opportunities. This transparency helps build trust and strengthens your supplier network for subsequent projects.

Bid Evaluation and Negotiation

Evaluation Methods

Effective bid evaluation requires a systematic approach that aligns with established project management phases. The evaluation process typically employs a weighted scoring matrix that considers technical capability, financial stability, past performance, and proposed methodology. Key evaluation criteria include price competitiveness, technical compliance, resource allocation, and risk management strategies.

Evaluators should utilize standardized assessment forms to maintain objectivity and ensure consistent scoring across all submissions. The process often involves multiple rounds of review, with initial screening followed by detailed technical and commercial evaluations. Best practices include implementing a clear scoring rubric (typically on a scale of 1-5 or 1-10), documenting all evaluation decisions, and maintaining confidentiality throughout the process.

To ensure transparency, evaluation committees should comprise diverse stakeholders with relevant expertise, including technical specialists, financial analysts, and project managers. This multi-disciplinary approach helps identify potential risks and opportunities while ensuring comprehensive bid assessment.

Negotiation Strategies

Effective negotiation in procurement requires a strategic balance of firmness and flexibility. Begin by thoroughly researching market rates, supplier capabilities, and alternative options to establish a strong negotiating position. Focus negotiations on total value rather than just price, considering factors like delivery terms, quality guarantees, and after-sales support.

Implement a structured approach using the “bracketing” technique, where your initial offer allows room for compromise while remaining within your acceptable range. Document all negotiation points and agreements in writing, and maintain professional relationships throughout the process.

Key negotiation tactics include:

– Using data-driven arguments to support your position

– Identifying mutual benefits and win-win opportunities

– Maintaining multiple supplier options to increase leverage

– Setting clear deadlines and milestones

– Establishing non-negotiable terms upfront

Remember that successful negotiations often lead to long-term partnerships. Always maintain transparency and ethical practices while seeking the best possible terms for your organization. Consider implementing regular review periods to ensure continued value and compliance with agreed terms.

Contract Award and Management

Contract Finalization

Contract finalization represents a critical milestone in the procurement process, requiring meticulous attention to detail and thorough review. The contract document must clearly outline scope, deliverables, timeline, payment terms, and performance metrics. Essential elements include detailed specifications, quality standards, site access protocols, and risk allocation between parties.

Industry best practices recommend incorporating dispute resolution mechanisms, change order procedures, and force majeure clauses. The contract should also address modern considerations such as sustainability requirements, digital collaboration protocols, and Building Information Modeling (BIM) responsibilities.

Before execution, all stakeholders must review and validate the contract terms. This includes legal counsel verification, insurance requirement confirmation, and bond documentation. Senior management approval ensures alignment with organizational objectives and risk tolerance levels.

Final contract execution should include proper signatures from authorized representatives, date stamps, and witness documentation where required. Maintain digital and physical copies in secure locations, with appropriate access controls and version tracking systems.

Performance Monitoring

Performance monitoring is crucial for maintaining procurement excellence and ensuring suppliers meet contractual obligations. Establish key performance indicators (KPIs) that align with project objectives, including delivery timeliness, quality standards, safety compliance, and cost management. Implement a systematic scoring system to evaluate supplier performance across these metrics, utilizing digital platforms for real-time tracking and reporting.

Regular performance reviews should be conducted, typically quarterly, to assess supplier compliance and identify areas for improvement. Document all findings, including both successes and challenges, to build a comprehensive supplier performance history. This data becomes invaluable for future procurement decisions and contract negotiations.

Consider implementing automated monitoring systems that track delivery schedules, quality control reports, and compliance documentation. These systems can generate alerts for potential issues before they impact project timelines. Additionally, maintain open communication channels with suppliers through structured feedback sessions, allowing for collaborative problem-solving and continuous improvement in the procurement process.

Successful performance monitoring ultimately leads to better risk management, improved supplier relationships, and optimized procurement outcomes.

Supply Chain Integration

Digital Integration

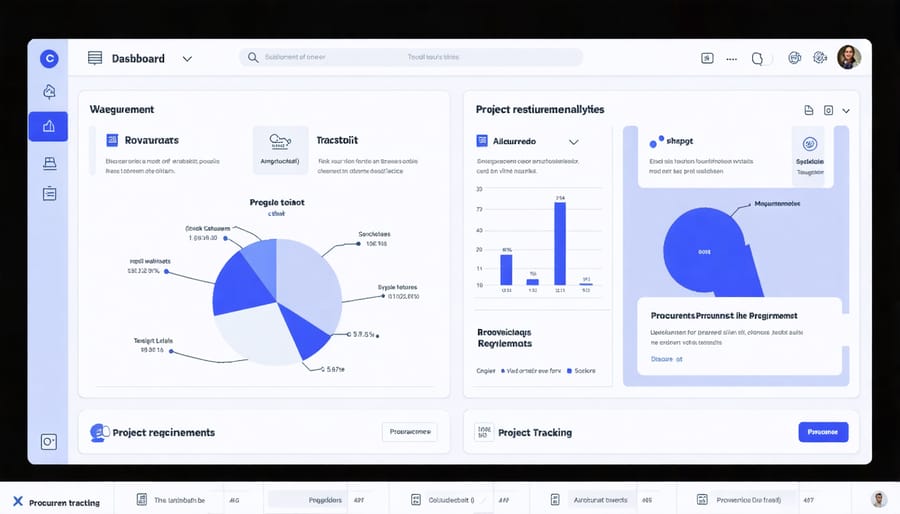

Modern procurement demands seamless digital integration to streamline processes and enhance efficiency. Construction companies are increasingly adopting comprehensive procurement management systems that consolidate vendor databases, automate purchase orders, and facilitate real-time tracking of materials and equipment. These platforms typically include features for document management, workflow automation, and collaborative approval processes.

Integration with Building Information Modeling (BIM) systems enables precise material quantity takeoffs and cost estimations, reducing waste and improving accuracy. AI-powered procurement solutions are revolutionizing the industry by predicting material needs, optimizing supplier selection, and identifying cost-saving opportunities.

Cloud-based procurement systems ensure accessibility across project sites and enable mobile approvals, while advanced analytics provide valuable insights into spending patterns and supplier performance. This digital transformation significantly reduces manual tasks, minimizes errors, and provides greater visibility into the entire procurement lifecycle, ultimately leading to better decision-making and improved project outcomes.

Continuous Improvement

Continuous improvement in procurement requires systematic evaluation and refinement of existing processes. Establish key performance indicators (KPIs) to measure supplier performance, delivery times, cost savings, and quality metrics. Regular data analysis helps identify bottlenecks and opportunities for optimization.

Implement a structured feedback loop involving stakeholders, suppliers, and project teams. Schedule quarterly reviews to assess procurement effectiveness and gather insights from completed projects. Document lessons learned and best practices to create a knowledge base for future reference.

Consider adopting digital procurement tools and automation technologies to streamline operations. Modern construction management platforms can provide real-time analytics and predictive insights, enabling proactive decision-making.

Invest in regular training for procurement staff to keep them updated with industry trends and emerging technologies. Foster relationships with key suppliers through partnership programs and collaborative improvement initiatives. This approach ensures your procurement process evolves with market demands while maintaining competitive advantages and operational efficiency.

Remember that continuous improvement is an ongoing journey rather than a destination. Regular assessment and adaptation of procurement strategies ensure long-term success and sustainable growth.

In today’s rapidly evolving construction landscape, effective procurement processes have become increasingly crucial for project success. The seven procurement steps outlined in this article form a comprehensive framework that enables construction professionals to navigate complex sourcing decisions while maximizing value and minimizing risks.

Key takeaways from these procurement steps emphasize the importance of thorough planning, strategic supplier evaluation, and robust contract management. Digital transformation continues to reshape traditional procurement methods, with emerging technologies like Building Information Modeling (BIM), artificial intelligence, and blockchain streamlining processes and improving transparency.

Looking ahead, several trends are set to influence construction procurement practices. Sustainability requirements will play a more prominent role in supplier selection, while data-driven decision-making will become standard practice. The industry can expect increased adoption of integrated procurement platforms that facilitate real-time collaboration and automated workflow management.

Success in modern construction procurement requires a balance between technological innovation and fundamental best practices. Organizations that embrace digital tools while maintaining strong relationships with suppliers and stakeholders will be better positioned to achieve optimal project outcomes. Additionally, the growing emphasis on risk management and compliance will continue to shape procurement strategies, making it essential for professionals to stay informed about industry developments and regulatory requirements.

By following these seven procurement steps and adapting to emerging trends, construction professionals can build more efficient, sustainable, and successful procurement processes that drive project excellence.