Industrial energy management systems represent a transformative force in modern manufacturing, delivering up to 30% reduction in energy costs while driving operational excellence. As global energy demands intensify and sustainability regulations tighten, these smart energy management systems have evolved from optional investments to mission-critical infrastructure. By integrating real-time monitoring, predictive analytics, and automated control systems, today’s industrial facilities can precisely optimize their energy consumption patterns across multiple processes and equipment types.

The convergence of Industrial Internet of Things (IIoT) sensors, advanced analytics platforms, and machine learning algorithms has created unprecedented opportunities for energy optimization at scale. Forward-thinking manufacturers now leverage these technologies to identify inefficiencies, predict maintenance needs, and automatically adjust operational parameters – all while maintaining production targets and quality standards. This systematic approach to energy management not only reduces operational costs but also strengthens regulatory compliance and advances corporate sustainability goals.

Recent case studies from leading manufacturers demonstrate that properly implemented energy management systems deliver ROI within 12-18 months through reduced energy waste, improved asset performance, and decreased maintenance costs. For facility managers and industrial leaders, understanding these systems’ capabilities and implementation strategies has become essential for maintaining competitive advantage in an increasingly energy-conscious marketplace.

The Evolution of Industrial Energy Management

Traditional vs. Smart Energy Management

Traditional energy management relied heavily on manual monitoring, periodic meter readings, and reactive maintenance approaches, often resulting in inefficient resource allocation and delayed response to energy waste. These conventional methods typically involved spreadsheet-based tracking and basic scheduling of equipment maintenance, limiting the ability to optimize energy consumption in real-time.

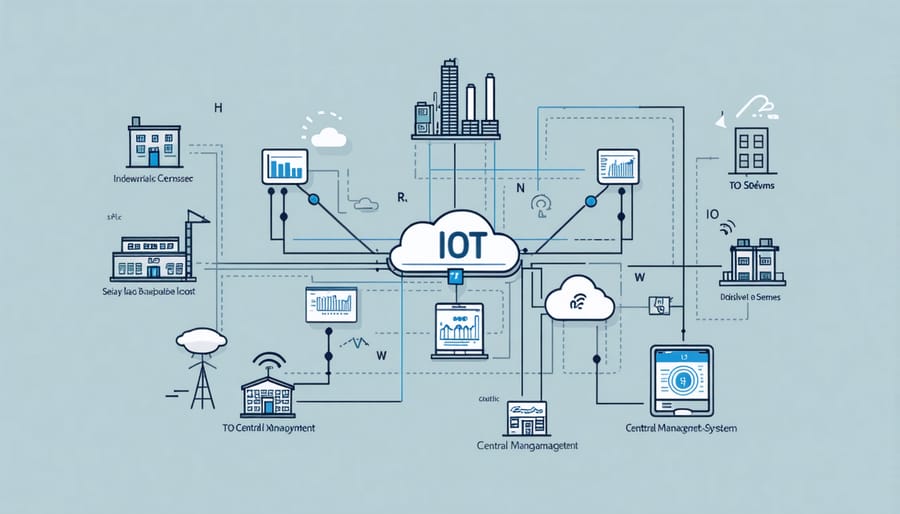

In contrast, modern smart energy management systems leverage IoT sensors, artificial intelligence, and cloud computing to provide comprehensive, real-time monitoring and control capabilities. These advanced systems continuously collect and analyze data from multiple sources, enabling predictive maintenance, automated load balancing, and dynamic energy optimization.

Smart systems offer significant advantages through features like automated fault detection, energy consumption pattern analysis, and demand response capabilities. While traditional methods might take days or weeks to identify energy inefficiencies, smart systems can detect and respond to anomalies within minutes. Additionally, modern solutions provide detailed analytics and reporting tools that enable data-driven decision-making and strategic energy planning.

The integration of machine learning algorithms allows these systems to learn from historical data and automatically adjust operational parameters for optimal energy efficiency, a capability entirely absent in traditional approaches.

Key Components of Modern IEMS

Modern industrial energy management systems comprise several interconnected components that work together to optimize energy consumption and enhance operational efficiency. At the core is an advanced monitoring and metering infrastructure that provides real-time data collection from various energy-consuming equipment and processes. This is supported by sophisticated analytics software that processes the collected data to identify consumption patterns, inefficiencies, and improvement opportunities.

Cloud-based data storage and processing capabilities enable seamless integration of multiple facility locations and remote monitoring capabilities. Smart sensors and IoT devices form the foundation of data collection, while automated control systems execute optimization strategies based on programmed parameters and real-time conditions.

Building automation systems (BAS) interface with the IEMS to coordinate HVAC, lighting, and other building systems. Advanced reporting tools generate customized analytics dashboards and compliance documentation, while predictive maintenance modules use machine learning algorithms to forecast equipment performance and prevent energy waste through early intervention.

These components are unified through a central management platform that enables facility managers to implement energy policies, track performance metrics, and make data-driven decisions for continuous improvement.

Real-Time Monitoring and Analytics

Sensor Networks and IoT Integration

Modern industrial energy management systems rely heavily on sophisticated sensor networks and Internet of Things (IoT) integration to deliver comprehensive facility monitoring and control. These systems typically incorporate multiple sensor types, including power meters, temperature sensors, occupancy detectors, and equipment-specific monitoring devices, all working in concert to provide real-time data collection and analysis.

The deployment strategy begins with a thorough facility assessment to determine optimal sensor placement and density. Critical areas such as production floors, HVAC systems, and high-consumption equipment receive particular attention, with redundant sensors often installed to ensure data reliability. These sensors communicate through various protocols, including Wi-Fi, Bluetooth Low Energy (BLE), and industrial ethernet, forming a robust mesh network that ensures consistent data transmission.

Integration with smart grid technology enables facilities to respond dynamically to grid conditions and participate in demand response programs. The IoT gateway serves as the central hub, processing incoming sensor data and transmitting it to the cloud-based management platform. This architecture enables advanced analytics, predictive maintenance, and automated response protocols.

Recent implementations have shown that well-designed sensor networks can detect energy waste patterns within hours of deployment, leading to immediate cost savings. The key to success lies in selecting appropriate sensor technology, ensuring proper calibration, and maintaining regular system health checks to guarantee accurate data collection and analysis.

Predictive Analytics and Machine Learning

Predictive analytics and machine learning technologies have revolutionized industrial energy management by enabling data-driven decision-making and automated optimization. Through AI-powered energy optimization, facilities can now forecast energy consumption patterns, identify potential equipment failures, and automatically adjust system parameters for peak efficiency.

These intelligent systems analyze vast amounts of historical and real-time data from sensors, meters, and building management systems to create accurate consumption models. By detecting patterns and correlations that humans might miss, machine learning algorithms can predict peak demand periods, optimize equipment scheduling, and recommend preventive maintenance actions.

Advanced analytics platforms can identify energy waste sources by comparing actual consumption against predicted baseline models. When integrated with building automation systems, these platforms can automatically implement corrective measures, such as adjusting HVAC settings based on occupancy patterns or weather forecasts.

Case studies from manufacturing facilities show that predictive analytics can reduce energy consumption by 15-25% while extending equipment life spans. The technology’s ability to learn from operational data means that system performance continues to improve over time, delivering increasingly accurate predictions and more refined optimization strategies.

For facility managers, these tools provide actionable insights through intuitive dashboards and automated reporting, enabling proactive energy management rather than reactive responses to issues.

Implementation Strategies

Assessment and Planning

Effective implementation of an industrial energy management system begins with a comprehensive assessment of current energy usage patterns and facility requirements. This evaluation typically involves conducting detailed energy audits, analyzing historical consumption data, and identifying key energy-intensive processes within the facility.

The assessment phase should include a thorough review of existing equipment efficiency, operational schedules, and maintenance practices. Energy professionals typically deploy advanced monitoring tools and data loggers to gather real-time information about energy consumption patterns across different departments and processes. This data serves as the baseline for identifying improvement opportunities and setting realistic energy reduction targets.

Once the assessment is complete, facility managers can develop a structured implementation plan that prioritizes initiatives based on potential impact and resource requirements. This plan should outline specific objectives, timelines, and responsibility assignments for each component of the energy management system. Key considerations include:

– Equipment upgrade requirements and associated costs

– Personnel training needs and resource allocation

– Integration with existing facility management systems

– Measurement and verification protocols

– Budget constraints and ROI expectations

The planning phase should also incorporate stakeholder feedback and address potential operational disruptions during implementation. A well-structured change management approach helps ensure buy-in from all levels of the organization and smooth transition to the new system.

Best practices recommend developing both short-term quick wins and long-term strategic initiatives. This balanced approach maintains momentum while working toward comprehensive energy optimization goals. The plan should also include contingency measures and regular review points to allow for adjustments based on early implementation results.

Integration with Existing Systems

Integrating modern Industrial Energy Management Systems (IEMS) with existing infrastructure requires a strategic approach that balances technological advancement with practical implementation. The key to successful integration lies in creating seamless connections between new IEMS components and legacy systems through carefully planned energy efficient retrofits and system upgrades.

Modern IEMS platforms typically employ protocol converters and gateway devices to establish communication between different system generations. These interfaces can translate data from older industrial protocols like Modbus or BACnet to contemporary IP-based communications, ensuring continuous data flow across the entire facility infrastructure.

A phased implementation approach often proves most effective, allowing organizations to gradually integrate new components while maintaining operational continuity. This method typically begins with the installation of smart meters and sensors on critical equipment, followed by the deployment of data collection systems and analytics platforms.

The integration process should prioritize:

– Installation of compatible communication interfaces

– Implementation of data normalization procedures

– Configuration of cross-system authentication protocols

– Establishment of unified monitoring dashboards

– Development of standardized reporting mechanisms

Organizations must also consider cybersecurity implications when connecting legacy systems to modern networks. This often involves implementing additional security layers, such as firewalls and encryption protocols, to protect vulnerable legacy components while maintaining system accessibility.

Success stories from manufacturing facilities demonstrate that proper integration can achieve energy savings of 15-30% while extending the useful life of existing equipment through better monitoring and predictive maintenance capabilities.

ROI and Benefits

Cost Savings and Efficiency Gains

Implementing industrial energy management systems consistently delivers substantial financial returns through multiple channels. Studies show that companies achieve an average building energy cost reduction of 20-30% within the first year of implementation.

The primary cost savings come from optimized energy consumption patterns, with automated systems adjusting usage based on real-time demand. Manufacturing facilities typically see immediate reductions in peak demand charges, often resulting in savings of $50,000-$200,000 annually for medium-sized operations.

Preventive maintenance capabilities of these systems generate additional savings by reducing equipment downtime and extending asset lifespans. Analysis of implementation data across various industries shows maintenance cost reductions of 15-25% and equipment lifespan increases of 20-30%.

Operational efficiency gains manifest through improved production scheduling, reduced waste, and optimized resource allocation. Companies report labor productivity increases of 10-15% through automated monitoring and control systems, while waste reduction initiatives typically yield 5-10% in material cost savings.

Return on investment (ROI) calculations consistently show payback periods of 12-24 months for comprehensive energy management systems, with some facilities achieving break-even points in as little as 8 months through aggressive implementation strategies and careful system optimization.

Environmental Impact and Compliance

Industrial energy management systems play a crucial role in reducing environmental impact while ensuring compliance with increasingly stringent regulations. These systems typically achieve 15-30% reduction in energy consumption, directly translating to lower greenhouse gas emissions and a smaller carbon footprint.

By implementing advanced monitoring and control mechanisms, facilities can optimize their energy usage patterns and identify opportunities for sustainable improvements. Real-time data analysis enables quick detection of inefficiencies and equipment malfunctions that could lead to unnecessary energy waste or environmental violations.

From a compliance perspective, modern energy management systems help organizations meet various environmental standards and regulations, including ISO 50001 and regional energy efficiency directives. These systems maintain detailed records of energy consumption, emissions, and improvement initiatives, simplifying the audit process and demonstrating commitment to environmental stewardship.

Case studies from manufacturing facilities show that automated energy management systems have helped achieve compliance with emissions trading schemes while generating substantial cost savings. For instance, a major automotive plant reduced its carbon emissions by 25% within two years of implementing an integrated energy management solution.

The systems also support sustainability reporting requirements by providing accurate data for environmental impact assessments and corporate sustainability reports. This capability has become increasingly important as stakeholders demand greater transparency in environmental performance and regulatory compliance.

Case Study: Success in Action

A compelling example of successful IEMS implementation can be found at the Sterling Manufacturing Complex, a large-scale industrial facility in Michigan that achieved remarkable results through systematic energy management transformation. In 2019, the facility faced rising energy costs and increasing pressure to meet sustainability targets, prompting management to invest in a comprehensive IEMS solution.

The implementation began with the installation of smart meters and sensors across their 500,000-square-foot facility, connecting various energy-consuming systems including HVAC, lighting, and manufacturing equipment. The IEMS platform integrated these components through a centralized control system, providing real-time monitoring and automated optimization capabilities.

Key implementation steps included:

– Initial energy audit and baseline establishment

– Strategic sensor placement and system integration

– Staff training and engagement programs

– Development of custom optimization algorithms

– Implementation of automated response protocols

Within the first year of operation, the results were significant:

– 23% reduction in overall energy consumption

– $875,000 in annual energy cost savings

– 31% decrease in peak demand charges

– 15% improvement in equipment efficiency

– ROI achieved in 18 months

The system’s predictive maintenance capabilities helped prevent three major equipment failures, saving an estimated $250,000 in potential downtime and repair costs. The facility’s energy team utilized the IEMS’s advanced analytics to identify and eliminate energy waste in their production processes, leading to optimized production schedules that balanced energy efficiency with output requirements.

Perhaps most notably, the system’s success led to a company-wide rollout across five additional facilities. The standardized approach to energy management has enabled Sterling to negotiate better utility rates and implement consistent energy-saving practices across their operations.

Critical success factors included:

– Strong executive support and clear communication of objectives

– Comprehensive staff training and engagement

– Regular system performance reviews and updates

– Integration with existing operational systems

– Data-driven decision-making processes

This case study demonstrates how a well-implemented IEMS can deliver substantial financial returns while supporting sustainability goals and improving operational efficiency. Sterling’s experience has become a benchmark for industrial energy management in the manufacturing sector.

Industrial energy management systems have become indispensable tools in modern manufacturing and industrial operations, demonstrating their vital role in achieving both sustainability goals and operational efficiency. As we’ve explored throughout this article, these systems offer comprehensive solutions for monitoring, analyzing, and optimizing energy consumption across industrial facilities.

The implementation of industrial energy management systems has consistently shown remarkable returns on investment, with many organizations reporting energy savings of 10-30% within the first year of deployment. These results, coupled with enhanced operational visibility and improved regulatory compliance, make a compelling case for wider adoption across industries.

Looking ahead, the future of industrial energy management systems appears increasingly sophisticated. The integration of artificial intelligence and machine learning capabilities will enable more precise predictive maintenance, automated optimization, and real-time decision-making. Industry experts anticipate that these systems will become more interconnected with other operational technologies, creating seamless industrial ecosystems that optimize not just energy usage, but entire production processes.

The growing emphasis on carbon neutrality and environmental responsibility will likely accelerate the evolution of these systems. We can expect to see more advanced features for carbon tracking, renewable energy integration, and sophisticated demand response capabilities. Additionally, the rise of edge computing and IoT technologies will enhance system responsiveness and data processing capabilities.

For organizations yet to implement these systems, the time to act is now. The combination of proven benefits, advancing technology, and increasing environmental pressures makes industrial energy management systems not just a smart investment, but a crucial component of future-ready industrial operations. Success in implementation relies on careful planning, stakeholder engagement, and a commitment to continuous improvement.